Description

SVRGBR heating cable is a specialized type of electrical cable designed for heating applications, particularly in environments where maintaining a consistent temperature is crucial. The acronym SVRGBR stands for “Silicone Rubber with Glass Fiber Braid.” This designation refers to the construction of the cable, which incorporates silicone rubber insulation with a glass fiber braid for added durability and heat resistance.

The silicone rubber insulation provides excellent electrical insulation properties while also being highly flexible, allowing the cable to be bent and routed easily without sacrificing performance. This flexibility is particularly advantageous in applications where the cable needs to be installed in tight spaces or around complex geometries.

The glass fiber braid serves multiple purposes in the construction of the heating cable. First and foremost, it provides mechanical protection, shielding the underlying conductors from damage due to abrasion, impact, or other forms of physical stress. Additionally, the glass fiber braid enhances the cable’s resistance to high temperatures, making it suitable for use in environments where heat exposure is a concern.

SVRGBR heating cables are commonly used in a variety of industrial and commercial applications where maintaining precise temperature control is essential. For example, they are frequently employed in freeze protection systems to prevent pipes and valves from freezing in cold climates.

These heating cables can also be utilized for floor heating in residential and commercial buildings, ensuring comfortable living and working environments during colder months.

One of the key advantages of SVRGBR heating cables is their ability to provide uniform heating along their entire length. This uniformity is achieved through the precise design of the cable and the selection of high-quality materials, ensuring consistent heat distribution without hot spots or cold zones.

This feature is critical in applications where maintaining a consistent temperature is paramount, such as in pharmaceutical manufacturing, food processing, or laboratory settings.

Another important characteristic of SVRGBR heating cables is their reliability and longevity. Thanks to their robust construction and high-quality materials, these cables are capable of withstanding harsh operating conditions, including exposure to moisture, chemicals, and extreme temperatures.

As a result, they offer a long service life with minimal maintenance requirements, making them a cost-effective solution for heating applications.

In addition to their performance and durability, SVRGBR heating cables are also highly customizable to meet the specific requirements of different applications. They are available in various lengths, wattages, and voltage ratings, allowing engineers and designers to select the appropriate cable for their particular heating needs.

Furthermore, these cables can be installed using different methods, including self-regulating, constant wattage, or mineral-insulated designs, depending on the application requirements and environmental conditions.

In summary, SVRGBR heating cables are a versatile and reliable solution for a wide range of heating applications. With their durable construction, uniform heating capabilities, and customization options, they provide an effective means of maintaining precise temperature control in industrial, commercial, and residential settings.

Whether used for freeze protection, floor heating, or process temperature maintenance, SVRGBR heating cables offer efficient and dependable performance, helping to ensure safe and comfortable environments in various industries and applications.

Where can you use a SVRGBR Heating Cable?

SVRGBR heating cables find extensive applications across various industries and settings due to their versatility, reliability, and efficiency in maintaining precise temperature control. These specialized heating cables are designed to withstand harsh environments and provide uniform heating, making them suitable for a wide range of uses. Let’s explore some of the common applications where SVRGBR heating cables excel:

1. Freeze Protection: SVRGBR heating cables are often used for freeze protection in pipes, valves, tanks, and other equipment exposed to cold temperatures. By providing controlled heat, these cables prevent freezing and maintain fluid flow in water supply lines, sprinkler systems, and industrial piping, ensuring uninterrupted operation even in extreme weather conditions.

2. Roof and Gutter De-icing: In regions prone to ice and snow buildup on roofs and gutters, SVRGBR heating cables offer an effective solution for preventing ice dams and icicle formation. Installed along roof edges, gutters, and downspouts, these cables generate heat to melt snow and ice, preventing potential damage to roofing materials and minimizing the risk of water infiltration into buildings.

3. Floor Heating: SVRGBR heating cables are widely used for radiant floor heating systems in residential, commercial, and industrial buildings. Installed beneath flooring materials such as tile, laminate, or concrete, these cables provide consistent warmth across the floor surface, creating comfortable indoor environments during cold weather while reducing energy consumption compared to traditional heating systems.

4. Process Heating: Industries such as manufacturing, food processing, and pharmaceuticals rely on SVRGBR heating cables for precise process heating applications. These cables can be incorporated into equipment, vessels, and pipelines to maintain optimal temperatures for chemical reactions, sterilization, drying, and other production processes, ensuring product quality and operational efficiency.

5. Snow Melting Systems: SVRGBR heating cables are integral components of snow melting systems installed in driveways, sidewalks, ramps, and outdoor stairs. By generating heat to melt snow and ice upon contact, these cables enhance safety and accessibility, reducing the need for manual snow removal and minimizing the risk of slip-and-fall accidents during winter months.

6. Greenhouse Heating: In agricultural settings, SVRGBR heating cables contribute to greenhouse heating systems by providing supplemental warmth to promote plant growth and protect delicate crops from frost damage. These cables can be embedded in soil beds or installed overhead to maintain optimal growing conditions and extend the growing season in colder climates.

7. Industrial Equipment: SVRGBR heating cables are employed for temperature maintenance and anti-condensation applications in various industrial equipment and machinery. They can be wrapped around pipes, valves, instrumentation, and process vessels to prevent heat loss, maintain viscosity of fluids, and avoid condensation buildup, ensuring reliable operation and prolonging equipment lifespan.

8. Oil and Gas Industry: In oil and gas production facilities, SVRGBR heating cables are utilized for pipeline heating, tank heating, and wellhead protection to prevent wax deposition, hydrate formation, and freezing of fluids in harsh environments. These cables help maintain flow rates, prevent equipment downtime, and ensure uninterrupted production operations in remote and challenging locations.

SVRGBR heating cables offer versatile solutions for diverse heating requirements across industries, including freeze protection, roof and gutter de-icing, floor heating, process heating, snow melting, greenhouse heating, and industrial applications. With their robust construction, uniform heating capabilities, and customizable designs, these cables provide efficient and reliable performance, contributing to enhanced safety, productivity, and comfort in various environments and applications.

Why should you choose a SVRGBR Heating Cable over other types?

Choosing an SVRGBR heating cable over other types offers numerous advantages, making it a preferred solution for various heating applications. SVRGBR heating cables stand out due to their unique combination of features and benefits, which include:

1. High Temperature Resistance: SVRGBR heating cables are designed to withstand high temperatures, thanks to their silicone rubber insulation and glass fiber braid construction. This high temperature resistance makes them ideal for use in environments where exposure to heat is a concern, ensuring reliable performance even in demanding conditions.

2. Excellent Flexibility: The silicone rubber insulation of SVRGBR heating cables provides exceptional flexibility, allowing the cable to be bent and routed easily without compromising its performance. This flexibility is particularly advantageous in applications where the cable needs to be installed in tight spaces or around complex geometries, providing greater versatility and ease of installation.

3. Uniform Heating: SVRGBR heating cables are engineered to provide uniform heating along their entire length, ensuring consistent temperature distribution without hot spots or cold zones. This uniform heating is critical in applications where maintaining precise temperature control is essential, such as in industrial processes or freeze protection systems.

4. Durability and Longevity: SVRGBR heating cables are built to last, with a robust construction and high-quality materials that enable them to withstand harsh operating conditions.

The glass fiber braid provides mechanical protection, shielding the underlying conductors from damage due to abrasion, impact, or other forms of physical stress. Additionally, the silicone rubber insulation offers excellent resistance to moisture, chemicals, and extreme temperatures, ensuring a long service life with minimal maintenance requirements.

5. Customizable Options: SVRGBR heating cables are available in a variety of lengths, wattages, and voltage ratings, allowing engineers and designers to select the appropriate cable for their specific heating needs. Furthermore, these cables can be customized with different heating elements and configurations to meet the requirements of different applications, providing greater flexibility and adaptability.

6. Wide Range of Applications: SVRGBR heating cables are suitable for a wide range of heating applications, including freeze protection, floor heating, process temperature maintenance, and more. Their versatility and reliability make them an ideal solution for industrial, commercial, and residential settings, offering efficient and dependable performance in various environments and conditions.

7. Cost-Effectiveness: Despite their superior performance and durability, SVRGBR heating cables offer a cost-effective heating solution compared to other types of heating systems. Their long service life, minimal maintenance requirements, and energy-efficient operation help to reduce overall operating costs, making them a cost-effective choice for heating applications.

In conclusion, choosing an SVRGBR heating cable offers numerous benefits, including high temperature resistance, excellent flexibility, uniform heating, durability, customizability, wide application versatility, and cost-effectiveness. These advantages make SVRGBR heating cables a preferred solution for various heating needs, providing reliable performance and peace of mind in a wide range of industrial, commercial, and residential settings.

Why should you choose SVR Trace for purchasing a SVRGBR Heating Cable?

Choosing SVR Trace for purchasing an SVRGBR heating cable offers several compelling reasons, making it the preferred choice for individuals and businesses in need of high-quality heating solutions. Here are some key factors to consider:

1. Expertise and Experience: SVR Trace boasts extensive expertise and experience in the field of heating solutions, particularly in the realm of SVRGBR heating cables. With a team of knowledgeable professionals, SVR Trace can provide expert guidance and support to help customers select the right heating cable for their specific needs and applications.

Whether you’re looking for freeze protection, floor heating, or process temperature maintenance, SVR Trace can offer tailored solutions to meet your requirements.

2. Wide Range of Products: SVR Trace offers a comprehensive range of SVRGBR heating cables to suit various heating applications. With different lengths, wattages, and voltage ratings available, customers have the flexibility to choose the perfect heating cable for their specific requirements.

Additionally, SVR Trace provides customization options, allowing customers to tailor the heating cable to their precise needs and specifications.

3. High-Quality Materials and Construction: SVR Trace prioritizes quality and reliability in all its products, including SVRGBR heating cables. These cables are constructed using high-quality materials, including silicone rubber insulation and a glass fiber braid, ensuring durability and longevity even in harsh operating conditions.

By choosing SVR Trace, customers can trust that they are investing in a premium-quality heating cable that will deliver consistent performance over time.

4. Exceptional Performance: SVRGBR heating cables from SVR Trace are designed to deliver exceptional performance, offering uniform heating along their entire length. This ensures consistent temperature distribution without hot spots or cold zones, making them ideal for applications where precise temperature control is essential.

Whether you’re heating pipes, floors, or industrial equipment, SVR Trace’s heating cables provide reliable and efficient performance.

5. Customization Options: SVR Trace understands that every heating application is unique, which is why they offer customization options for their SVRGBR heating cables. Whether you need a specific length, wattage, or voltage rating, SVR Trace can tailor the heating cable to meet your exact requirements.

This level of customization ensures that customers get a heating solution that is perfectly suited to their needs, maximizing efficiency and performance.

6. Reliable Customer Support: SVR Trace is committed to providing excellent customer service and support throughout the purchasing process and beyond. Whether you have questions about product selection, installation, or maintenance, SVR Trace’s team of experts is available to assist you every step of the way.

With responsive and reliable customer support, SVR Trace ensures a smooth and hassle-free experience for all its customers.

7. Competitive Pricing: Despite offering high-quality products and exceptional service, SVR Trace maintains competitive pricing to ensure affordability for its customers. By choosing SVR Trace for purchasing an SVRGBR heating cable, customers can enjoy excellent value for money without compromising on quality or performance.

In summary, choosing SVR Trace for purchasing an SVRGBR heating cable offers numerous benefits, including expertise and experience, a wide range of products, high-quality materials and construction, exceptional performance, customization options, reliable customer support, and competitive pricing.

With SVR Trace as your trusted partner, you can be confident that you’re getting the best heating solution for your specific needs, backed by superior quality, reliability, and service.

What is the purpose of the SVRGBR Heating Cable?

The purpose of an SVRGBR heating cable is to provide efficient and reliable heat generation for a variety of applications across different industries. SVRGBR heating cables are specifically designed to deliver uniform heating along their entire length, making them ideal for situations where maintaining a consistent temperature is crucial.

The acronym SVRGBR stands for “Silicone Rubber with Glass Fiber Braid,” which highlights the key components of these specialized cables.

One of the primary purposes of SVRGBR heating cables is freeze protection. In cold climates, pipes, valves, and other critical infrastructure are susceptible to freezing, which can lead to costly damage and downtime.

SVRGBR heating cables are installed along the length of pipes or around valves to prevent freezing by maintaining a constant temperature. This ensures that water can flow freely, preventing damage and maintaining the integrity of the system.

Another common application of SVRGBR heating cables is floor heating. These cables are installed beneath flooring materials, such as tile or laminate, to provide comfortable warmth in residential, commercial, and industrial buildings. SVRGBR heating cables deliver consistent heat distribution across the floor surface, creating a cozy and inviting environment while reducing the need for traditional heating systems.

SVRGBR heating cables are also utilized for process temperature maintenance in industrial settings. In manufacturing facilities, chemical plants, and other industrial environments, precise temperature control is essential for ensuring product quality and optimizing production processes.

SVRGBR heating cables can be integrated into tanks, vessels, and other equipment to maintain the required temperature levels, ensuring that processes run smoothly and efficiently.

In addition to these primary purposes, SVRGBR heating cables have various other applications across different industries. They are used for roof and gutter de-icing to prevent the formation of ice dams, which can cause water damage to buildings. SVRGBR heating cables are also employed for snow melting on driveways, sidewalks, and ramps, enhancing safety and accessibility during winter months.

The versatility of SVRGBR heating cables makes them suitable for a wide range of environments and conditions. Whether it’s protecting pipes from freezing, heating floors for comfort, maintaining process temperatures in industrial settings, or preventing ice and snow buildup, SVRGBR heating cables offer an effective and reliable solution.

One of the key advantages of SVRGBR heating cables is their ability to provide uniform heating without hot spots or cold zones. This ensures consistent temperature distribution, which is essential for achieving optimal performance in various applications.

Additionally, SVRGBR heating cables are durable and long-lasting, capable of withstanding harsh operating conditions and offering a low-maintenance heating solution.

In summary, the purpose of an SVRGBR heating cable is to deliver efficient and reliable heat generation for a wide range of applications, including freeze protection, floor heating, process temperature maintenance, roof and gutter de-icing, and snow melting. With their uniform heating capabilities, durability, and versatility, SVRGBR heating cables offer an effective solution for maintaining optimal temperatures and enhancing safety and comfort in various environments.

How hot does a SVRGBR Heating Cable get?

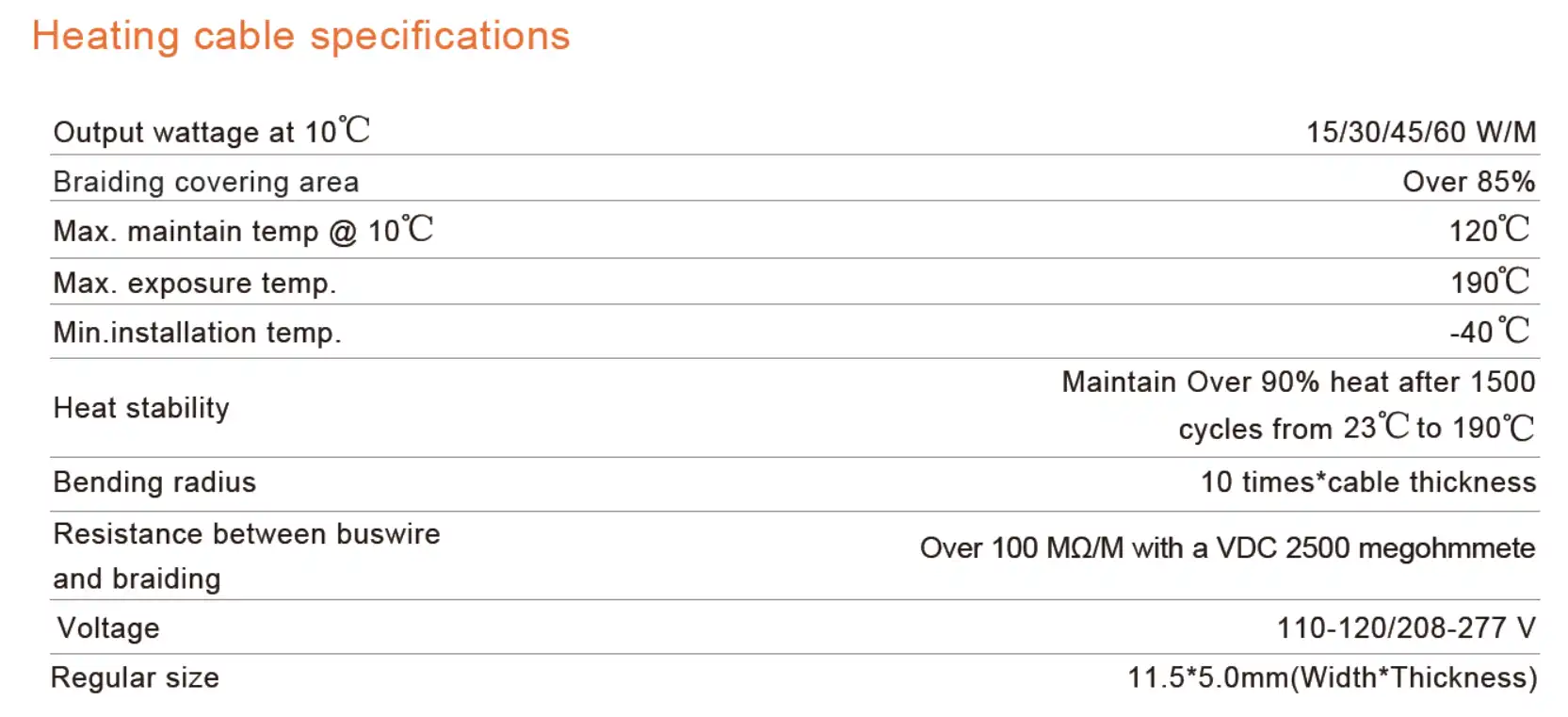

The temperature that an SVRGBR heating cable can reach depends on several factors, including the design of the cable, the electrical power supplied to it, and the surrounding environment. SVRGBR heating cables are engineered to withstand high temperatures, making them suitable for a wide range of heating applications. However, the actual temperature achieved by the cable will vary based on specific conditions.

SVRGBR heating cables typically operate within a temperature range of -60°C to 200°C (-76°F to 392°F). This range covers both extreme cold environments where the cable may need to provide freeze protection and high-temperature environments where the cable may be used for process heating or other industrial applications.

The temperature achieved by an SVRGBR heating cable is primarily determined by the electrical power supplied to it. These cables are available in different wattages, allowing users to select the appropriate power rating based on their heating requirements. Higher wattage cables can generate more heat and reach higher temperatures, while lower wattage cables produce less heat and operate at lower temperatures.

In addition to electrical power, the ambient temperature and insulation properties of the surrounding environment also play a role in determining the temperature achieved by an SVRGBR heating cable. In cold environments, the cable may need to work harder to maintain a desired temperature, potentially reaching higher temperatures to compensate for heat loss to the surroundings.

Conversely, in warmer environments, the cable may not need to generate as much heat to achieve the same temperature, resulting in lower operating temperatures.

SVRGBR heating cables are designed to operate safely within their specified temperature range. The silicone rubber insulation and glass fiber braid construction provide excellent thermal stability and resistance to high temperatures, ensuring that the cable remains reliable and durable even under extreme conditions.

However, it’s essential to ensure that the cable is properly installed and used according to manufacturer guidelines to prevent overheating and potential damage.

In conclusion, SVRGBR heating cables are capable of reaching temperatures up to 200°C (392°F), depending on factors such as electrical power, ambient temperature, and insulation properties.

These cables are designed to operate safely within their specified temperature range, making them suitable for a wide range of heating applications, from freeze protection to industrial process heating. By selecting the appropriate cable and following proper installation and usage guidelines, users can ensure reliable performance and efficient heat generation in various environments and conditions.

How is SVRGBR cable heating calculation done?

The calculation of heating for an SVRGBR (Silicone Rubber with Glass Fiber Braid) cable involves several factors, including the desired temperature, the characteristics of the cable, and the specific conditions of the application.

While the calculation process may vary slightly depending on the exact requirements and specifications, the following steps provide a general overview of how SVRGBR cable heating calculation is typically done:

1. Determine Heating Requirements: The first step in the calculation process is to determine the heating requirements for the application. This involves identifying the desired temperature that needs to be maintained or achieved, as well as any specific heating needs based on the environment or materials involved.

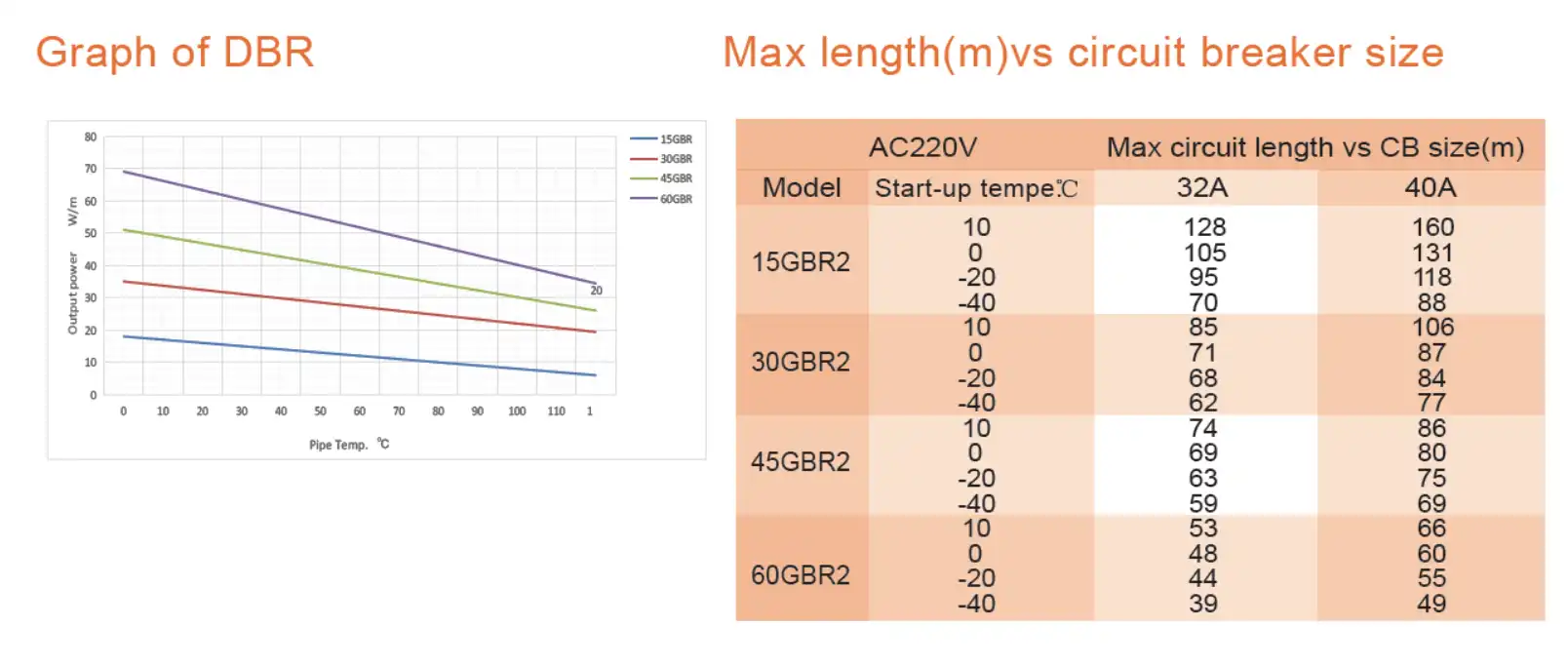

2. Select Cable Specifications: Once the heating requirements are known, the next step is to select the appropriate SVRGBR heating cable specifications.

This includes considering factors such as cable length, wattage rating, voltage rating, and insulation properties. The selection of cable specifications should be based on the heating requirements identified in the previous step, as well as any other relevant considerations such as installation constraints or environmental conditions.

3. Calculate Heat Output: With the selected cable specifications in hand, the next step is to calculate the heat output of the cable. This involves using the wattage rating of the cable to determine the amount of heat generated per unit length.

The heat output calculation may also take into account factors such as the thermal conductivity of the cable materials and any insulation or sheathing present.

4. Consider Heat Loss: In addition to calculating the heat output of the cable, it’s also important to consider any heat loss that may occur during operation. Heat loss can occur through factors such as conduction, convection, and radiation, as well as through insulation or other materials surrounding the cable.

By accounting for heat loss, the calculated heating output can be adjusted to ensure that the desired temperature is achieved at the target location.

5. Verify Safety and Efficiency: Finally, before proceeding with installation and operation, it’s essential to verify that the calculated heating output meets safety standards and efficiency requirements.

This may involve conducting simulations or calculations to ensure that the cable operates within its specified temperature range and that it can safely provide the necessary heating without overheating or causing damage.

Overall, the calculation of heating for an SVRGBR cable involves a careful assessment of the heating requirements, selection of appropriate cable specifications, calculation of heat output, consideration of heat loss, and verification of safety and efficiency. By following these steps and ensuring accurate calculations,

it’s possible to design and install SVRGBR heating cables that effectively meet the heating needs of various applications while operating safely and efficiently.

Reviews

There are no reviews yet.