Description

SVRDBR heating cable, also known as self-regulating heating cable, is a versatile and efficient solution for preventing freeze-ups and maintaining desired temperatures in various applications. This innovative heating technology adapts its power output based on changes in ambient temperature, making it highly energy-efficient and self-regulating.

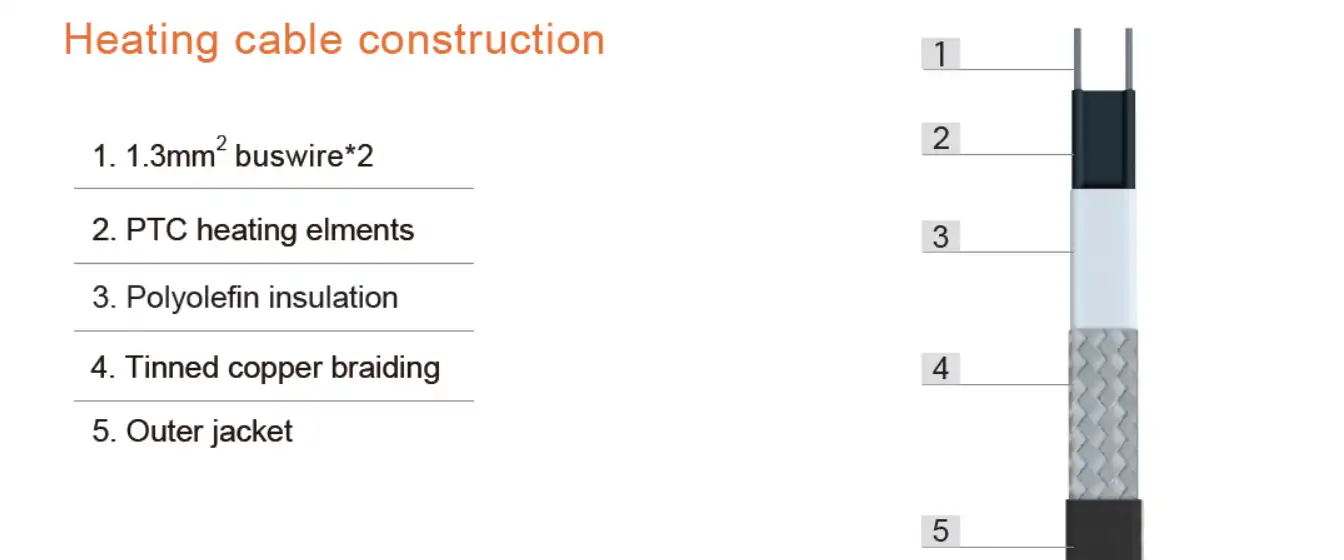

The term “SVRDBR” stands for “Self-Regulating Variable Duty Band Resistor,” which essentially describes how the cable functions. It consists of a conductive core, typically made of a carbon-loaded polymer, surrounded by two parallel bus wires. The core’s conductivity varies with temperature, allowing it to automatically adjust its heat output in response to environmental changes.

One of the key advantages of SVRDBR heating cable is its ability to regulate heat output along its entire length. This means that as temperatures drop, the cable generates more heat to compensate, and as temperatures rise, the heat output decreases accordingly. This self-regulating feature not only ensures consistent and reliable temperature maintenance but also prevents overheating and potential damage to the system.

SVRDBR heating cable finds wide applications across various industries, including residential, commercial, and industrial sectors. Common uses include freeze protection for pipes, tanks, and valves in plumbing systems, temperature maintenance for process piping and equipment in manufacturing facilities, and snow melting for driveways, sidewalks, and roofs.

In residential settings, SVRDBR heating cable is often used to prevent frozen pipes during cold weather. By wrapping the cable around exposed pipes or installing it inside the pipes, homeowners can ensure a continuous flow of water and avoid costly damage caused by burst pipes.

In commercial and industrial environments, SVRDBR heating cable plays a crucial role in maintaining optimal temperatures for processes and equipment. For example, in the food and beverage industry, it is utilized for maintaining the temperature of storage tanks, pipelines, and processing equipment to ensure product quality and safety.

SVRDBR heating cable is also employed in construction projects for concrete curing and temperature control. By embedding the cable within concrete structures, contractors can accelerate the curing process and prevent thermal cracking, resulting in stronger and more durable concrete.

Installation of SVRDBR heating cable is relatively straightforward, requiring minimal maintenance once in place. The cable can be cut to length as needed and easily installed using clips, adhesive tapes, or cable ties. Additionally, it can be used in conjunction with temperature and moisture sensors to provide advanced control and monitoring capabilities.

Overall, SVRDBR heating cable offers a cost-effective, energy-efficient, and reliable solution for temperature maintenance and freeze protection in various applications.

Its self-regulating feature, along with easy installation and minimal maintenance requirements, makes it a preferred choice for both residential and commercial use. Whether it’s preventing frozen pipes, maintaining process temperatures, or melting snow and ice, SVRDBR heating cable provides a versatile and efficient heating solution.

Where can you use a SVRDBR Heating Cable?

As mentioned before, SVRDBR heating cable is an innovative tool for freezing prevention and maintaining desired temperatures in various applications. This innovative heating technology adapts its power output based on changes in ambient temperature, making it highly energy-efficient and self-regulating.

The term “SVRDBR” stands for “Self-Regulating Variable Duty Band Resistor,” which essentially describes how the cable functions. It consists of a conductive core, typically made of a carbon-loaded polymer, surrounded by two parallel bus wires. The core’s conductivity varies with temperature, allowing it to automatically adjust its heat output in response to environmental changes.

One of the key advantages of SVRDBR heating cable is its ability to regulate heat output along its entire length. This means that as temperatures drop, the cable generates more heat to compensate, and as temperatures rise, the heat output decreases accordingly. This self-regulating feature not only ensures consistent and reliable temperature maintenance but also prevents overheating and potential damage to the system.

SVRDBR heating cable finds wide applications across various industries, including residential, commercial, and industrial sectors. Common uses include freeze protection for pipes, tanks, and valves in plumbing systems, temperature maintenance for process piping and equipment in manufacturing facilities, and snow melting for driveways, sidewalks, and roofs.

In residential settings, SVRDBR heating cable is often used to prevent frozen pipes during cold weather. By wrapping the cable around exposed pipes or installing it inside the pipes, homeowners can ensure a continuous flow of water and avoid costly damage caused by burst pipes.

In commercial and industrial environments, SVRDBR heating cable plays a crucial role in maintaining optimal temperatures for processes and equipment. For example, in the food and beverage industry, it is utilized for maintaining the temperature of storage tanks, pipelines, and processing equipment to ensure product quality and safety.

SVRDBR heating cable is also employed in construction projects for concrete curing and temperature control. By embedding the cable within concrete structures, contractors can accelerate the curing process and prevent thermal cracking, resulting in stronger and more durable concrete.

Installation of SVRDBR heating cable is relatively straightforward, requiring minimal maintenance once in place. The cable can be cut to length as needed and easily installed using clips, adhesive tapes, or cable ties. Additionally, it can be used in conjunction with temperature and moisture sensors to provide advanced control and monitoring capabilities.

Overall, SVRDBR heating cable offers a cost-effective, energy-efficient, and reliable solution for temperature maintenance and freeze protection in various applications. Its self-regulating feature, along with easy installation and minimal maintenance requirements, makes it a preferred choice for both residential and commercial use.

Whether it’s preventing frozen pipes, maintaining process temperatures, or melting snow and ice, SVRDBR heating cable provides a versatile and efficient heating solution.

Why should you choose a SVRDBR Heating Cable over other types?

When it comes to selecting the right heating cable for various applications, it’s essential to consider factors such as efficiency, reliability, durability, and safety. Among the plethora of options available, SVRDBR heating cable stands out as a superior choice for numerous reasons. In this comprehensive guide, we’ll delve into why SVRDBR heating cable should be your preferred option over others.

1. Enhanced Efficiency

SVRDBR heating cables are designed with advanced technology to provide efficient heating performance. Their construction ensures uniform heat distribution along the entire length of the cable, minimizing energy wastage and ensuring optimal heating output. This efficiency translates to cost savings for users, making SVRDBR heating cables a financially prudent choice in the long run.

2. Versatility

One of the key advantages of SVRDBR heating cables is their versatility. They can be utilized in a wide range of applications, including freeze protection, temperature maintenance, and heat tracing in various industries such as oil and gas, chemical processing, food and beverage, and more. Whether it’s for residential, commercial, or industrial purposes, SVRDBR heating cables offer flexible solutions to meet diverse heating requirements.

3. Durability and Longevity

SVRDBR heating cables are engineered to withstand harsh environmental conditions and maintain optimal performance over an extended lifespan. Constructed from high-quality materials such as fluoropolymer insulation and robust conductors, these cables exhibit exceptional durability, ensuring reliable operation even in the most demanding environments. With minimal maintenance requirements, SVRDBR heating cables offer long-term reliability and peace of mind to users.

4. Safety Features

Safety is paramount when it comes to heating applications, and SVRDBR heating cables prioritize safety through various built-in features. These cables are designed to meet rigorous industry standards and regulations, ensuring compliance with safety requirements. Additionally, SVRDBR heating cables incorporate features such as overheat protection and ground-fault protection to prevent accidents and ensure the well-being of personnel and property.

5. Ease of Installation

Installing heating cables can be a complex process, but SVRDBR heating cables are designed for ease of installation. With flexible designs and customizable lengths, these cables can be easily installed in various configurations to suit specific requirements. Furthermore, comprehensive installation guidelines and support from manufacturers simplify the installation process, reducing downtime and minimizing installation costs.

6. Energy Efficiency

In today’s environmentally conscious world, energy efficiency is a crucial consideration for heating systems. SVRDBR heating cables are engineered to maximize energy efficiency, minimizing heat loss and reducing energy consumption. By efficiently delivering heat to targeted areas, these cables help optimize energy usage and reduce operational costs, making them an environmentally friendly choice.

7. Reliability and Performance

When it comes to heating applications, reliability is non-negotiable. SVRDBR heating cables are renowned for their reliability and consistent performance, ensuring uninterrupted operation even in challenging conditions. Whether it’s maintaining critical temperatures in industrial processes or preventing pipe freeze-ups in harsh climates, SVRDBR heating cables deliver reliable performance when it matters most.

In summary, SVRDBR heating cables offer a multitude of benefits that make them the preferred choice for various heating applications. From enhanced efficiency and versatility to durability, safety, and ease of installation, SVRDBR heating cables excel on multiple fronts.

Whether you’re looking for a heating solution for residential, commercial, or industrial use, SVRDBR heating cables provide unmatched reliability, performance, and cost-effectiveness, making them the ideal choice for your heating needs.

Why should you choose SVR Trace for purchasing a SVRDBR Heating Cable?

SVR Trace stands out as the optimal choice when considering the purchase of an SVRDBR heating cable due to several compelling reasons. As a consumer, it’s crucial to prioritize quality, reliability, and efficiency when investing in heating solutions, and SVR Trace offers a comprehensive package that fulfills these requirements and more.

First and foremost, SVR Trace boasts a stellar reputation built on years of experience and expertise in the field of heating technology. Their commitment to innovation and continuous improvement ensures that their products are at the forefront of industry standards. When opting for SVR Trace, customers can rest assured that they are purchasing from a trusted brand known for delivering top-notch performance and durability.

One of the key advantages of SVRDBR heating cables offered by SVR Trace is their unparalleled efficiency. These cables are designed to deliver precise and uniform heating, ensuring optimal energy utilization while effectively preventing ice and snow buildup in various applications. Whether it’s for residential, commercial, or industrial use, SVRDBR heating cables excel in maintaining temperature consistency, thereby enhancing safety and reducing operational costs in the long run.

Moreover, SVR Trace places a strong emphasis on product quality and reliability. Each SVRDBR heating cable undergoes rigorous testing and quality assurance procedures to meet stringent standards. By adhering to strict manufacturing protocols and utilizing high-quality materials, SVR Trace guarantees the longevity and performance of their heating cables, even in the most demanding environments and harsh weather conditions.

Another noteworthy aspect of SVR Trace’s offerings is their versatility and adaptability. SVRDBR heating cables come in various configurations and specifications to accommodate diverse heating requirements and installation scenarios. Whether it’s for roof and gutter de-icing, pipe freeze protection, or concrete curing, SVR Trace provides customizable solutions tailored to specific needs, ensuring optimal performance and ease of installation.

In addition to superior product quality, SVR Trace prioritizes customer satisfaction and support. Their team of knowledgeable professionals is readily available to provide technical assistance, guidance, and after-sales service to ensure a seamless experience for customers. Whether it’s selecting the right heating solution, troubleshooting issues, or addressing inquiries, SVR Trace is committed to going above and beyond to meet customer needs and expectations.

Furthermore, SVR Trace places a strong emphasis on sustainability and environmental responsibility. By offering energy-efficient heating solutions, such as SVRDBR heating cables, they help reduce carbon footprint and promote eco-friendly practices. With a focus on innovation and eco-conscious design, SVR Trace aligns with the growing demand for sustainable solutions in today’s increasingly environmentally conscious world.

In conclusion, choosing SVR Trace for purchasing an SVRDBR heating cable is a decision backed by reliability, efficiency, quality, and customer satisfaction. With a proven track record of excellence, innovative technology, and unwavering commitment to customer service, SVR Trace stands out as the premier choice for heating solutions. By opting for SVR Trace, customers can enjoy peace of mind knowing that they are investing in a trusted brand that delivers unparalleled performance, durability, and value.

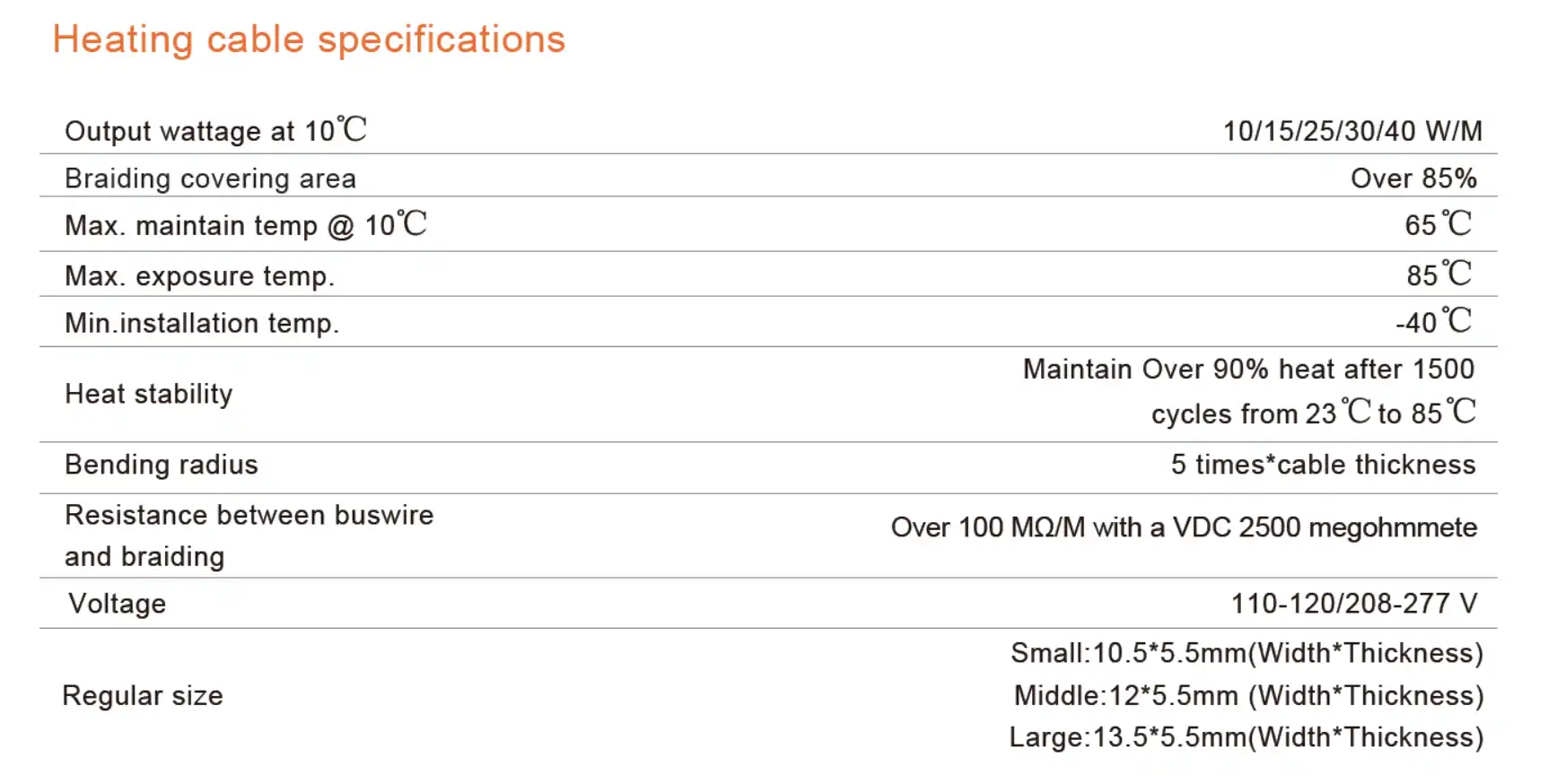

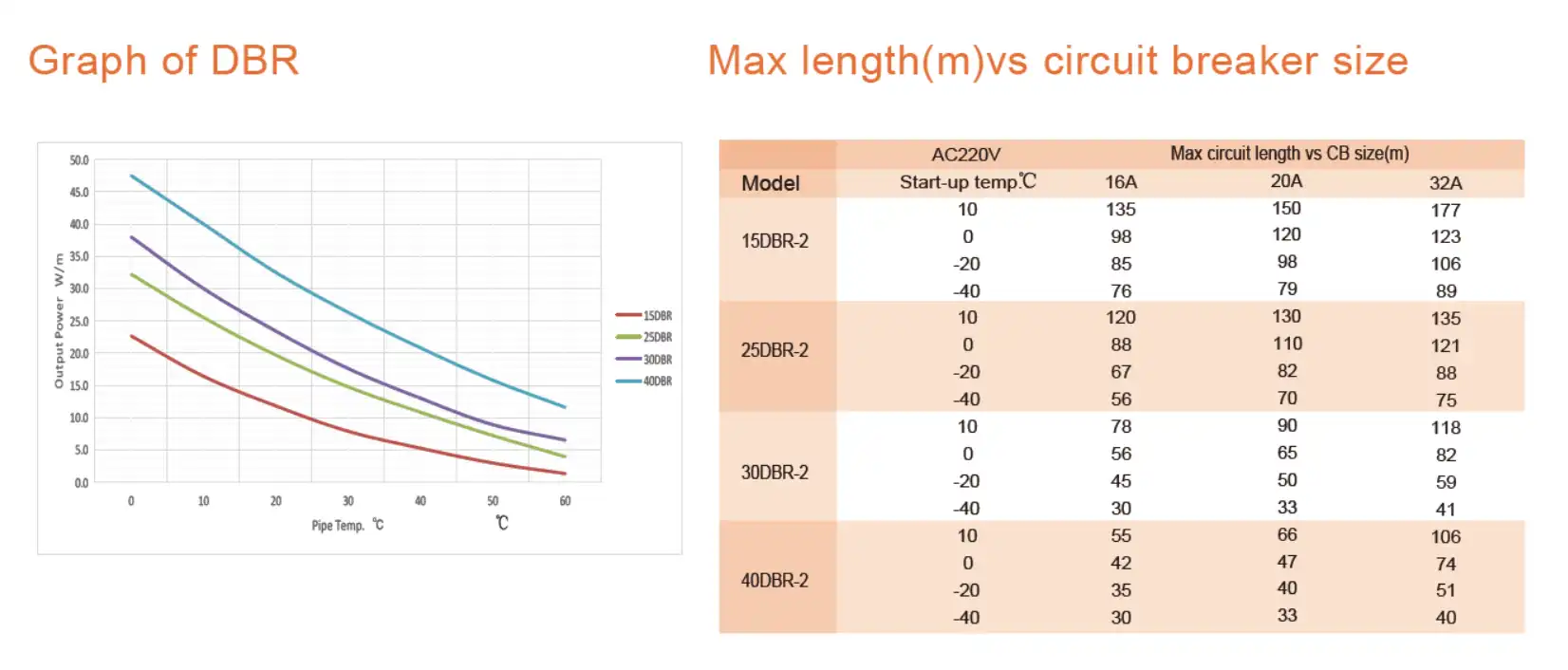

What are SVRDBR Heating Cable specifications?

Understanding SVRDBR Heating Cable Pricing: Factors and Considerations

SVRDBR heating cables are essential components in various industries, providing efficient and reliable heat tracing solutions for pipelines, tanks, and other equipment. Understanding the pricing of SVRDBR heating cables involves considering multiple factors, including material costs, installation requirements, and maintenance expenses. This article aims to delve into the intricacies of SVRDBR heating cable pricing, offering insights into what influences the costs and how businesses can make informed decisions.

Factors Influencing SVRDBR Heating Cable Pricing:

1. Material Quality and Durability:

The quality of materials used in manufacturing SVRDBR heating cables significantly impacts their pricing. High-quality materials ensure durability, longevity, and efficient heat transfer, which are crucial for reliable performance in demanding industrial environments. Suppliers offering cables with superior materials may command higher prices, but the long-term benefits often outweigh the initial investment.

2. Length and Thickness:

The length and thickness of SVRDBR heating cables directly affect their pricing. Longer cables require more materials and labor for production, resulting in higher costs. Similarly, thicker cables designed for higher wattage or insulation purposes may also come at a premium. Businesses must accurately determine the required cable length and thickness based on their specific heating requirements to optimize cost-effectiveness.

3. Power Output and Energy Efficiency:

SVRDBR heating cables are available in various power ratings, ranging from low-wattage options for frost protection to high-wattage cables for process temperature maintenance. Higher power output cables typically command higher prices due to their increased heating capacity. However, investing in energy-efficient cables can lead to long-term cost savings by reducing operational expenses related to electricity consumption.

4. Installation Complexity:

The complexity of installing SVRDBR heating cables can influence pricing significantly. Factors such as the accessibility of the installation site, the presence of obstacles, and the need for specialized equipment or expertise can impact labor costs. Additionally, installations requiring custom configurations or intricate routing may incur additional expenses. Proper planning and collaboration with experienced installers can help mitigate these costs.

5. Regulatory Compliance and Certification:

SVRDBR heating cables must comply with industry standards and safety regulations to ensure reliable performance and mitigate risks. Suppliers offering certified cables that meet relevant standards may price their products higher to cover compliance testing and certification expenses. However, choosing certified cables can provide peace of mind and minimize liabilities associated with non-compliance.

SVRDBR heating cable pricing is influenced by a multitude of factors, including material quality, length, power output, installation complexity, and regulatory compliance. Businesses seeking cost-effective heat tracing solutions must carefully evaluate these factors and strike a balance between upfront expenses and long-term benefits. By understanding the nuances of SVRDBR heating cable pricing and making informed decisions, organizations can optimize performance, reliability, and efficiency in their industrial heating applications.

SVRDBR (Self-Regulating Variable Resistance Dual Bus Regulated) heating cables are installed to provide efficient heat tracing solutions for various industrial applications. The installation process typically involves several key steps:

1. Preparation: Before installation, ensure that the work area is clean, dry, and free from any debris or obstructions. Inspect the surface where the heating cable will be installed to ensure it is suitable for adherence.

2. Layout Design: Plan the layout of the heating cable system according to the specific heating requirements and the configuration of the pipes or equipment to be traced. Take into account factors such as pipe diameter, insulation thickness, and any bends or valves that may require special attention.

3. Mounting: Secure the SVRDBR heating cable onto the surface of the pipe or equipment using appropriate fixing materials such as adhesive-backed tapes, metal bands, or clips. Ensure that the cable is evenly spaced and properly positioned to provide uniform heating coverage.

4. Connection: Connect the heating cable to the power supply according to the manufacturer’s instructions. SVRDBR cables are self-regulating, meaning they automatically adjust their power output based on the surrounding temperature. However, it’s essential to follow the recommended guidelines for connecting multiple cables or junction boxes to maintain proper electrical continuity.

5. Insulation: Insulate the heating cable and the traced surface to minimize heat loss and improve energy efficiency. Use insulation materials suitable for the operating temperatures and environmental conditions of the application. Pay special attention to areas such as pipe joints and valves, where heat loss is more likely to occur.

6. Testing: Before commissioning the heating system, perform thorough testing to ensure proper installation and functionality. Check for continuity, insulation resistance, and proper power output of the heating cables. Verify that the traced surface reaches the desired temperature under normal operating conditions.

7. Documentation and Maintenance: Keep detailed records of the installation process, including cable layout diagrams, electrical connections, and testing results. Establish a regular maintenance schedule to inspect the heating system for any signs of damage, deterioration, or malfunction. Promptly address any issues to prevent potential downtime or safety hazards.

By following these steps and adhering to best practices for installation and maintenance, SVRDBR heating cables can provide reliable and efficient heat tracing solutions for a wide range of industrial applications.

What is the average lifespan of SVRDBR Heating Cable?

The average lifespan of SVRDBR (Self-Regulating Variable Resistance Dual Bus Regulated) heating cables typically ranges from 10 to 20 years, depending on various factors such as usage conditions, environmental factors, maintenance practices, and quality of installation.

1. Usage Conditions: The operating conditions to which the heating cable is subjected can significantly impact its lifespan. Cables used in harsh environments with extreme temperatures, corrosive chemicals, or mechanical stresses may experience accelerated wear and degradation.

2. Environmental Factors: Environmental factors such as exposure to sunlight, moisture, humidity, and atmospheric contaminants can affect the longevity of the heating cable. Proper insulation and protection measures can help mitigate the impact of these factors and extend the cable’s lifespan.

3. Maintenance Practices: Regular maintenance and inspection play a crucial role in preserving the functionality and lifespan of SVRDBR heating cables. Periodic checks for damage, wear, or deterioration, as well as prompt repair or replacement of any faulty components, can prevent premature failure and ensure optimal performance.

4. Quality of Installation: The quality of installation also influences the lifespan of heating cables. Proper mounting, secure connections, and adherence to manufacturer’s guidelines can minimize stress on the cable and reduce the risk of damage or failure over time.

5. Manufacturer Quality and Warranty: Choosing high-quality SVRDBR heating cables from reputable manufacturers can contribute to longer lifespans and better overall performance. Additionally, some manufacturers offer warranties or guarantees on their products, providing assurance of quality and reliability.

Overall, with proper installation, maintenance, and usage in appropriate conditions, SVRDBR heating cables can provide reliable heat tracing solutions for many years, offering cost-effective and efficient temperature maintenance for industrial applications.

Reviews

There are no reviews yet.