Description

Heating cable with inactive copper, also known as heat trace cables or heat tracing cables, are specialized electrical cables designed to provide warmth and prevent freezing in various applications.

Unlike regular electrical cables, which conduct electricity to power devices or lights, heating cable with inactive copper generates heat along their length when electricity passes through them. The inactive copper refers to the conductive material within the cable that does not actively contribute to the heating process but serves as a conductor for the electric current.

Heating cable with inactive copper is typically composed of several layers, each serving a specific purpose. The innermost layer consists of the conductive material, often copper, which carries the electrical current.

Surrounding this core is a layer of insulation, usually made of materials such as fluoropolymers or thermoplastic polymers, to prevent electrical leakage and ensure safety. Additionally, an outer jacket provides further protection from external elements and mechanical damage.

Heating cable with inactive copper finds application in various industries and settings where temperature maintenance or freeze protection is critical. One common use is in pipe heating, where the cables are wrapped around pipes to prevent them from freezing in cold climates. They are also employed in roof and gutter de-icing systems to melt snow and ice buildup, enhancing safety and preventing structural damage.

Another application of a heating cable with inactive copper is in floor heating systems, where they are installed beneath flooring materials to provide radiant heat. This type of heating offers comfort and energy efficiency, particularly in residential and commercial spaces. Additionally, these cables are utilized in industrial processes to maintain optimal temperatures in tanks, vessels, and equipment.

The installation of a heating cable with inactive copper requires careful planning and adherence to safety standards. Proper selection of cable type, wattage, and installation method is essential to ensure effective performance and longevity. Additionally, the cables must be installed by qualified professionals to prevent electrical hazards and ensure compliance with building codes and regulations.

One advantage of a heating cable with inactive copper is their versatility and flexibility in various applications. They can be customized to fit specific lengths and configurations, making them suitable for both large-scale industrial installations and smaller residential projects. Furthermore, advancements in technology have led to the development of energy-efficient heating cables with improved performance and durability.

However, it’s essential to consider the operational costs associated with heating cables, as they consume electricity during use. Proper insulation and control systems can help optimize energy usage and minimize operating expenses. Regular maintenance and inspection are also crucial to detect any issues promptly and ensure continued functionality.

In conclusion, a heating cable with inactive copper are valuable assets in temperature maintenance and freeze protection applications across different industries.

Their ability to generate controlled heat along their length makes them indispensable for preventing damage and ensuring safety in various environments. With proper installation, maintenance, and management, these cables can provide reliable performance and contribute to operational efficiency and comfort.

Characteristics

Series type heating cable with inactive copper areas

There is no extra thickness at the cold junction

Excellent connection surface

Power supply: Up to 30 W/m

On request up to 500 V

Where can you use a Heating Cable with Inactive Copper?

A heating cable with inactive copper, also known as heat trace cables, offer versatile solutions for temperature maintenance and freeze protection in a wide range of applications across various industries.

Their unique ability to generate controlled heat makes them invaluable in environments where maintaining specific temperatures or preventing freezing is critical. Here are some common areas where heating cables with inactive copper find extensive use:

1. Pipelines and Plumbing: One of the primary applications of heating cables is in pipe heating systems. Heating cable with inactive copper is wrapped around pipes, valves, and fittings to prevent them from freezing in cold climates.

In industries such as oil and gas, chemical processing, and water treatment, maintaining fluid flow is essential, and heating cables help prevent costly downtime and damage due to frozen pipes.

2. Roof and Gutter De-Icing: In regions prone to snow and ice buildup, a heating cable with inactive copper is installed along the edges of roofs and inside gutters to melt snow and prevent ice dams. Ice dams can lead to water infiltration, roof damage, and even structural issues. Heating cables provide an effective solution to mitigate these risks and enhance safety during winter months.

3. Floor Heating Systems: A heating cable with inactive copper is widely used in radiant floor heating systems. These cables are installed beneath flooring materials, such as tile, laminate, or hardwood, to provide consistent and efficient heating. Radiant floor heating offers comfort and energy savings in residential, commercial, and industrial buildings, providing warmth from the ground up.

4. Industrial Processes: Various industrial processes require precise temperature control to optimize efficiency and ensure product quality. A heating cable with inactive copper is used in tanks, vessels, and equipment to maintain specific temperatures during manufacturing, storage, and transportation. Industries such as food and beverage, pharmaceuticals, and petrochemicals rely on heating cables to meet regulatory requirements and operational standards.

5. Freeze Protection in Outdoor Equipment: Outdoor equipment, such as pumps, valves, and meters, are susceptible to freezing in cold weather conditions. Heating cables are installed around these components to prevent freezing and ensure continuous operation. This is particularly crucial in remote locations, where access for manual intervention may be limited.

6. Snow Melting Systems: A heating cable with inactive copper is utilized in snow melting systems for driveways, walkways, and outdoor stairs. These systems automatically detect snowfall and activate the heating cables to melt snow and ice, providing safer access and reducing the need for manual snow removal.

7. Greenhouses and Agricultural Applications: Heating cables are employed in greenhouses and agricultural settings to maintain optimal growing conditions for plants. They prevent frost damage and promote consistent growth by providing supplementary heat during colder months.

8. Cold Storage Facilities: Cold storage facilities require precise temperature control to preserve perishable goods. Heating cables are installed to prevent freezing in refrigeration systems, ensuring product integrity and compliance with regulatory standards.

In conclusion, a heating cable with inactive copper offers versatile solutions for temperature maintenance and freeze protection in diverse applications. From industrial processes to residential heating systems, these cables play a crucial role in ensuring operational efficiency, safety, and comfort.

This cable is a flexible series heating cable with the particular feature of incorporating

copper lengths inside it so as to create inactive areas which may subsequently be cut,

providing an excellent connection surface.

A heating cable with inactive copper is mainly incorporated in household electrical or refrigeration

equipment and special, mass-produced machines requiring protection against freezing

or temperature maintenance.

Cable structure: Silicone insulation series type heating cable + inactive copper areas. With advancements in technology and installation practices, heating cables continue to provide reliable and cost-effective solutions for a wide range of industries and environments.

How does a Heating Cable with Inactive Copper work?

A heating cable with inactive copper, also known as a self-regulating heating cable, operates on a fascinating principle that involves a unique blend of materials and electrical properties to generate heat. This type of heating cable is widely used in various applications ranging from residential heating systems to industrial processes where maintaining a consistent temperature is crucial.

At its core, a self-regulating heating cable consists of two main components: a conductive core and a semi-conductive polymer matrix. The conductive core typically comprises copper or other conductive materials, while the polymer matrix contains conductive particles dispersed throughout its structure. These particles enable the cable to self-regulate its heat output based on changes in temperature and electrical resistance.

The key to the functionality of a heating cable with inactive copper lies in the behavior of the semi-conductive polymer matrix. When an electrical current is applied to the cable, the conductive particles within the polymer matrix create multiple conductive paths. This allows electricity to flow through the cable, generating heat in the process.

However, what sets self-regulating heating cables apart is their ability to adapt their heat output based on temperature changes. As the temperature increases, the resistance of the polymer matrix also increases, limiting the flow of electrical current and consequently reducing the heat output.

Conversely, when the temperature decreases, the resistance decreases as well, allowing more current to flow and increasing the heat output. This self-regulating behavior ensures that the cable maintains a consistent temperature regardless of fluctuations in the surrounding environment.

The role of the inactive copper in this process is primarily to provide structural support and conductivity to the cable. While the copper itself does not actively contribute to the self-regulating behavior, it serves as a reliable conductor for the electrical current. Additionally, the presence of copper helps to enhance the overall efficiency and durability of the heating cable.

In practical applications, heating cables with inactive copper are used for a wide range of purposes. In residential settings, they are commonly installed to prevent pipes from freezing during cold weather or to provide supplemental heat in areas where traditional heating systems may be insufficient. In industrial settings, these cables are utilized for process heating, temperature maintenance, and frost protection in pipelines, tanks, and other equipment.

Overall, a heating cable with inactive copper offers a versatile and efficient solution for maintaining optimal temperatures in various environments.

Its self-regulating properties, combined with the conductivity of copper, make it a reliable and cost-effective option for heating applications where precise temperature control is essential. Whether in residential, commercial, or industrial settings, this innovative technology continues to play a crucial role in ensuring comfort, safety, and efficiency.

Why should you choose a Heating Cable with Inactive Copper?

Choosing a heating cable with inactive copper can offer several advantages in temperature maintenance and freeze protection applications. These advantages stem from the unique properties and capabilities of these specialized cables, making them a preferred choice for various industries and settings.

One of the primary reasons to choose a heating cable with inactive copper is its effectiveness in preventing freezing and maintaining optimal temperatures.

The design of these cables allows for controlled heat generation along their length, which can be precisely regulated to meet specific requirements. Whether it’s preventing pipes from freezing in cold climates or maintaining consistent temperatures in industrial processes, heating cables with inactive copper provide reliable and uniform heating.

Additionally, the presence of inactive copper within the cable ensures efficient electrical conductivity without contributing to the heating process.

This feature enhances safety by minimizing the risk of overheating or electrical hazards. The insulation layers surrounding the conductive core further enhance safety by preventing electrical leakage and protecting against mechanical damage.

Another reason to choose heating cables with inactive copper is their versatility and adaptability to various applications. These cables can be customized to fit specific lengths and configurations, allowing for flexible installation in different environments. Whether it’s wrapping them around pipes, embedding them in floors, or installing them in tanks and vessels, a heating cable with inactive copper offers versatility and ease of integration.

Moreover, a heating cable with inactive copper are known for their durability and longevity. Constructed with high-quality materials and built to withstand harsh conditions, these cables can provide reliable performance over extended periods. Proper installation and maintenance further enhance their lifespan, ensuring long-term effectiveness and cost savings.

Energy efficiency is another significant benefit of choosing a heating cable with inactive copper. By generating heat only where needed, these cables minimize energy waste and help optimize operational costs. Advanced control systems and insulation techniques can further enhance energy efficiency, allowing for precise temperature control and reduced electricity consumption.

Furthermore, a heating cable with inactive copper offer ease of installation and maintenance. Qualified professionals can install these cables quickly and efficiently, minimizing downtime and disruption to operations. Routine maintenance, including inspections and testing, helps identify any issues early on and ensures continued functionality and safety.

In addition to their practical benefits, choosing a heating cable with inactive copper can also contribute to sustainability efforts. By preventing freezing and reducing the need for traditional heating methods, these cables help conserve energy and reduce greenhouse gas emissions. This environmental stewardship aligns with the growing emphasis on sustainability in various industries and communities.

In conclusion, selecting a heating cable with inactive copper offers numerous advantages in temperature maintenance and freeze protection applications. From their effectiveness and safety features to their versatility and energy efficiency, these cables provide reliable heating solutions for diverse needs. By choosing a heating cable with inactive copper, businesses and individuals can ensure optimal performance, safety, and sustainability in their operations.

Why should you choose SVR Trace for purchasing a Heating Cable with Inactive Copper?

SVR Trace stands out as a top choice for purchasing a heating cable with inactive copper for several compelling reasons. With a commitment to quality, reliability, and customer satisfaction, SVR Trace offers a range of products and services that make it the preferred supplier in the industry.

First and foremost, SVR Trace prioritizes the quality of its heating cables with inactive copper. The company sources materials from trusted suppliers and adheres to stringent manufacturing standards to ensure that its products meet the highest quality benchmarks. Each heating cable undergoes rigorous testing and inspection processes to guarantee optimal performance and durability.

By choosing SVR Trace, customers can have confidence in the reliability and longevity of their heating cable systems.

Furthermore, SVR Trace prides itself on its extensive industry experience and technical expertise. The company’s team of professionals possesses in-depth knowledge of heating cable technology and application requirements.

Whether customers need assistance with product selection, system design, or installation guidance, SVR Trace offers comprehensive support every step of the way. With access to expert advice and support, customers can make informed decisions and achieve optimal results with their heating cable systems.

Another key advantage of choosing SVR Trace is the company’s commitment to innovation and continuous improvement. SVR Trace invests in research and development initiatives to stay at the forefront of technological advancements in the industry.

By leveraging the latest innovations, SVR Trace delivers cutting-edge heating cable solutions that offer enhanced performance, efficiency, and functionality. Customers can benefit from state-of-the-art products that deliver superior results and value over the long term.

Moreover, SVR Trace distinguishes itself through its customer-centric approach and personalized service. The company understands that each customer’s needs and requirements are unique, and it strives to provide tailored solutions that address specific challenges and objectives.

Whether customers require standard heating cable products or customized solutions, SVR Trace works closely with them to deliver solutions that meet their exact specifications and preferences. With a focus on customer satisfaction, SVR Trace builds strong relationships and earns the trust and loyalty of its clientele.

In addition to its exceptional product quality and customer service, SVR Trace offers competitive pricing and value-added benefits. The company is committed to providing cost-effective solutions that deliver maximum value and return on investment for its customers.

From competitive pricing structures to flexible payment options and warranty coverage, SVR Trace ensures that customers receive the best possible value for their investment in heating cable systems.

Furthermore, SVR Trace maintains a strong reputation for reliability, integrity, and professionalism in the industry. The company upholds high ethical standards and business practices, fostering trust and confidence among its customers, partners, and stakeholders. With a proven track record of success and a commitment to excellence, SVR Trace has earned its position as a trusted leader in the heating cable industry.

In conclusion, SVR Trace offers compelling reasons to choose it as the preferred supplier for purchasing heating cable with inactive copper. With a focus on quality, expertise, innovation, customer service, and value, SVR Trace delivers unmatched solutions that meet the diverse needs and requirements of its clientele.

Whether customers require standard products or customized solutions, they can rely on SVR Trace to deliver reliable, high-performance heating cable systems that provide long-lasting benefits and satisfaction.

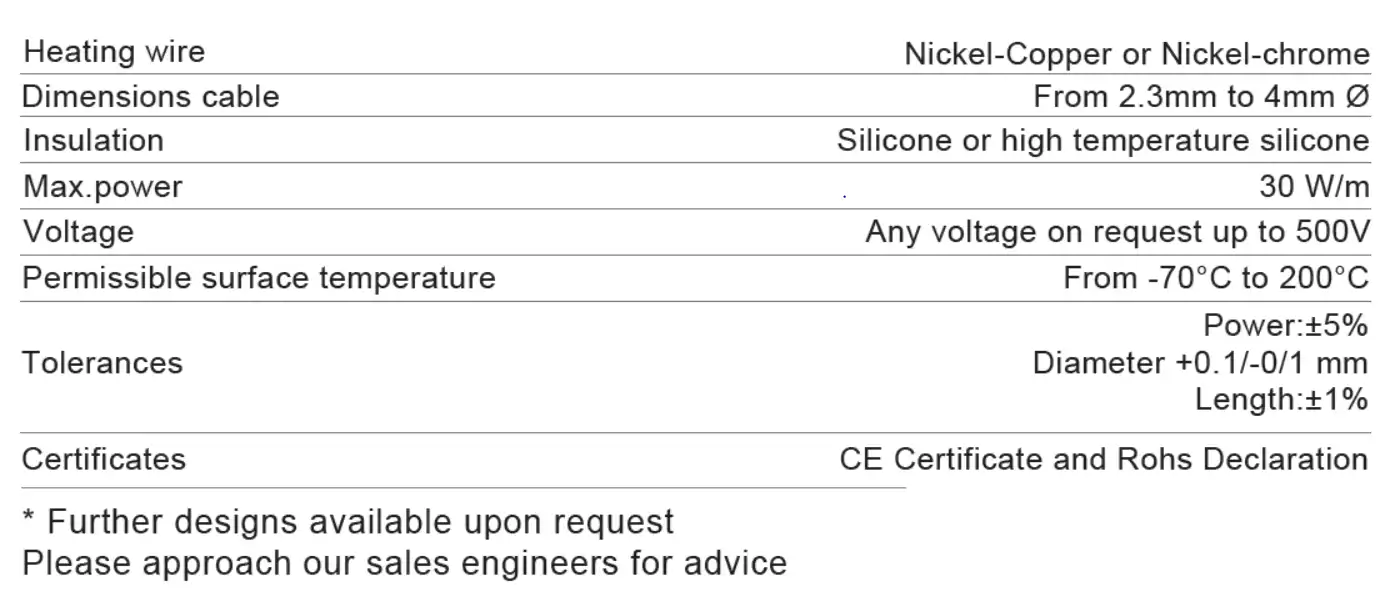

What are Technical Features of a Heating Cable with Inactive Copper?

What is the lifespan of a Heating Cable with Inactive Copper?

The lifespan of a heating cable with inactive copper can vary depending on several factors including the quality of materials, installation methods, usage conditions, and maintenance practices. However, these cables are generally designed to have a long service life, often ranging from 10 to 30 years or more.

A heating cable with inactive copper conductors is commonly used for various applications such as pipe freeze protection, roof and gutter de-icing, floor heating, and temperature maintenance in industrial processes. The inactive copper conductors are typically insulated with materials such as fluoropolymer or thermoplastic, providing protection against moisture, chemicals, and mechanical damage.

One of the key factors affecting the lifespan of a heating cable with inactive copper is the quality of the materials used in their construction. High-quality materials and manufacturing processes can result in cables that are more durable and less prone to degradation over time. Additionally, proper installation by trained professionals is crucial for ensuring optimal performance and longevity.

Usage conditions also play a significant role in determining the lifespan of heating cables. Cables installed in harsh environments with extreme temperatures, corrosive substances, or excessive mechanical stress may experience accelerated wear and degradation. Regular maintenance and inspections can help identify any issues early on and prevent premature failure.

Proper sizing and design of the heating cable with inactive copper system are essential for efficient operation and longevity. Oversized or undersized cables may lead to excessive energy consumption, overheating, or inadequate heating performance, which can shorten the lifespan of the cables. It’s important to follow manufacturer recommendations and industry standards when selecting and installing heating cables.

In addition to proper installation and maintenance, environmental factors such as exposure to sunlight, moisture, chemicals, and physical damage can impact the lifespan of a heating cable with inactive copper. Protective measures such as insulation, cable trays, and conduits can help mitigate these risks and extend the life of the cables.

Regular inspections and testing of a heating cable with inactive copper can help identify any issues or potential failures before they occur. This may include visual inspections, electrical testing, and thermal imaging to detect hot spots or abnormalities in the cable system.

Overall, heating cable with inactive copper can have a lifespan of 10 to 30 years or more, depending on various factors such as quality, installation, usage conditions, and maintenance practices. By following best practices for installation, operation, and maintenance, it’s possible to maximize the lifespan and performance of these heating cable systems.

How much is the price of a Heating Cable with Inactive Copper?

Firstly, it’s crucial to understand the purpose of a heating cable with inactive copper. A heating cable with inactive copper are designed to generate heat in order to prevent freezing or to maintain a desired temperature in pipelines, roofs, gutters, and other critical infrastructure. The inactive copper serves as a conductor, aiding in the efficient distribution of heat along the cable’s length.

When considering the price of a heating cable with inactive copper, one must take into account the length required for the intended application. These cables are typically sold by the foot or meter, and longer lengths will naturally incur higher costs. Additionally, the type of cable plays a significant role in pricing. There are various types available, including self-regulating, constant wattage, and mineral insulated cables, each with its own features and price points.

Brand reputation and quality also influence the price of a heating cable with inactive copper. Established brands with a track record of reliability and performance often command higher prices due to their reputation for durability and effectiveness. Conversely, lesser-known brands or generic options may offer lower prices but could sacrifice quality and reliability.

Furthermore, the specific application requirements can impact the price of heating cables. For instance, cables intended for use in hazardous environments or extreme temperatures may require additional certifications or specialized construction, resulting in higher costs. Additionally, accessories such as thermostat controls, junction boxes, and installation hardware should be factored into the overall price.

In terms of pricing range, a heating cable with inactive copper can vary widely. On the lower end of the spectrum, basic self-regulating or constant wattage cables may cost anywhere from $1 to $5 per foot or meter. Mid-range options with additional features or higher wattage ratings could range from $5 to $15 per foot or meter. At the higher end, specialized cables designed for harsh environments or industrial applications may exceed $20 per foot or meter.

It’s essential to note that while upfront costs are a consideration, the overall value and long-term performance of heating cables should also be evaluated. Investing in high-quality cables from reputable brands may result in lower maintenance and operating costs over time, ultimately providing a greater return on investment.

In conclusion, the price of a heating cable with inactive copper varies depending on factors such as length, type, brand, and application requirements. While there are options available across a wide price range, selecting a reputable brand and considering long-term value are crucial factors in making an informed purchasing decision.

Reviews

There are no reviews yet.