Heat-Tracing in the Hydrogen Process: Optimizing Efficiency and Ensuring Safety

In the realm of hydrogen production, heat-tracing technology plays a pivotal role in achieving optimal efficiency and ensuring the safety of  operations. By maintaining consistent temperatures throughout the system, heat-tracing systems contribute to efficient hydrogen generation while preventing potential hazards. This article explores the significance of heat-tracing and its diverse applications in the hydrogen production process.

operations. By maintaining consistent temperatures throughout the system, heat-tracing systems contribute to efficient hydrogen generation while preventing potential hazards. This article explores the significance of heat-tracing and its diverse applications in the hydrogen production process.

Efficiency and Safety Considerations

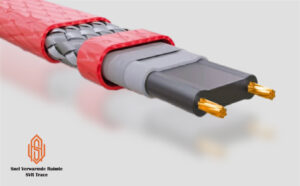

Heat-tracing systems employ self-regulating cables that minimize heat loss and optimize energy efficiency. By maintaining a consistent temperature, these systems enhance the overall efficiency of the hydrogen production process. Heat-tracing also prevents the formation of cold spots, condensation, or ice buildup within equipment, which can lead to blockages and reduce productivity.

Applications in the Hydrogen Process

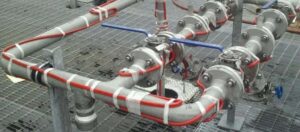

Furthermore, heat-tracing finds extensive applications throughout the various stages of hydrogen production. During the preheating stage, heat-tracing systems facilitate the warming of feedstock gases, ensuring efficient reactions. By maintaining the required temperature within the reformer unit, which commonly employs steam methane reforming, heat-tracing minimizes temperature fluctuations and maximizes the yield of high-quality hydrogen.

Safety Aspects

Moreover, heat-tracing technology significantly contributes to safety in the hydrogen production process. Maintaining optimal temperatures reduces the risk of thermal stress and potential equipment failure, safeguarding both the equipment and personnel involved. Heat-tracing also prevents the accumulation of flammable gases, mitigating the risk of explosions. By keeping process equipment and piping at appropriate temperatures, it minimizes the potential for hydrogen leaks and associated safety hazards.

Challenges and Solutions

While heat-tracing offers numerous benefits, it is important to address potential challenges. One common challenge is the risk of overheating. However, modern heat-tracing systems incorporate advanced control mechanisms to ensure precise temperature regulation, effectively avoiding overheating risks. Additionally, the design complexity of heat-tracing systems can pose a challenge. However, with the support of experienced engineers and advanced modeling tools, efficient and effective heat-tracing designs can be achieved.

Integration with Process Control Systems

We can seamlessly integrate heat-tracing systems with process control systems, enhancing their efficiency and ease of use. By integrating temperature sensors and controllers, heat-tracing can be optimized based on real-time conditions. This allows for automatic adjustments to maintain desired temperatures and respond promptly to any deviations. Such integration ensures the system operates at peak efficiency while minimizing manual intervention.

Advancements in Heat-Tracing Technology

In recent years, significant advancements have been made in heat-tracing technology, further improving efficiency and safety. Self-regulating cables have become more reliable and energy-efficient, offering better temperature control. New materials and coatings have been developed to withstand harsh operating conditions, extending the lifespan of heat-tracing systems. Additionally, improved insulation materials help minimize heat loss and enhance overall system performance.

Cost Considerations

When implementing heat-tracing systems, it is essential to consider the associated costs. While the initial investment may be higher, the long-term benefits in terms of improved efficiency, reduced downtime, and enhanced safety outweigh the upfront expenses. Additionally, advancements in heat-tracing technology have led to more cost-effective solutions, making it a viable option for hydrogen production facilities.

Conclusion

Heat-tracing technology is an indispensable component of the hydrogen production process, optimizing efficiency and ensuring safety. By maintaining consistent temperatures, heat-tracing systems enable efficient hydrogen generation and prevent potential hazards. The integration of heat-tracing with process control systems, advancements in technology, and cost considerations further enhance its value. As the demand for hydrogen continues to rise, we can not overstate the importance of heat-tracing in achieving a reliable, efficient, and safe hydrogen production process. By embracing heat-tracing technology, the industry can pave the way for a sustainable and clean energy future.