Introduction

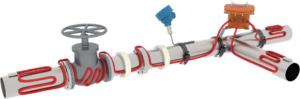

Heat tracing cables are a crucial technology in various industries, ensuring optimal temperature control for pipelines, tanks, and other equipment. By employing an active heating system, these cables prevent freezing, maintain viscosity, and safeguard against damage. This article explores the benefits, applications, and installation considerations of this product.

Benefits of Heat Tracing Cables:

Heat tracing cables offer numerous advantages. Firstly, they maintain consistent temperatures, preventing freezing and maintaining fluid flow. Additionally, they enhance safety by preventing pipe bursts, which can lead to costly damages. Moreover, heat tracing cables improve energy efficiency and reduce operational costs by minimizing heat loss.

Applications of Heat Tracing Cables:

Heat tracing cables find extensive use across industries. In the oil and gas sector, they ensure the smooth transportation of crude oil, preventing blockages caused by low temperatures. In chemical plants, these cables maintain optimal temperatures for sensitive processes, protecting both equipment and personnel. This kind of heating cables are also vital in food processing facilities, preventing freezing or overheating of products.

Installation Considerations:

When installing heat tracing cables, several factors require careful consideration. Firstly, proper cable selection is crucial, as different cables have varying temperature ranges and power output capabilities. Secondly, the cable layout should be designed to maximize heat distribution. Additionally, it is important to insulate the system adequately to minimize heat loss. Lastly, regular maintenance and monitoring are necessary to ensure optimal performance.

Now let’s delve into the benefits of heat tracing cables in more detail.

Benefit 1: Consistent Temperature Control

Heat tracing cables maintain consistent temperatures within pipelines, preventing freezing and ensuring uninterrupted flow. This is especially critical in cold climates where low temperatures can cause blockages and operational disruptions.

Moreover, this type of cables offer enhanced safety features.

Benefit 2: Preventing Pipe Bursts

By preventing freezing, this product eliminates the risk of pipe bursts. This safeguarding measure prevents leaks and potential hazards, saving both time and money associated with repairs and cleanup.

In addition to safety, these cables contribute to improved energy efficiency.

Benefit 3: Minimizing Heat Loss

Heat tracing cables minimize heat loss from pipes, tanks, and equipment. By maintaining optimal temperatures, they reduce the need for excessive heating, leading to significant energy savings and decreased operational costs.

Let’s now explore the various applications of heat tracing cables.

Application 1: Oil and Gas Industry

In the oil and gas sector, this type of cable is used to maintain the flow of crude oil and prevent blockages caused by low temperatures. By ensuring continuous transportation, these cables optimize production and minimize downtime.

These cables also play a vital role in chemical plants.

Application 2: Chemical Processing

Chemical plants rely on this product to maintain specific temperatures during various processes. Whether it is heating fluids or preventing solidification, these cables help protect sensitive equipment and ensure efficient operations.

Another significant application of this product is found in the food processing industry.

Application 3: Food Processing

In food processing facilities, this type of heating system prevents freezing or overheating of products. They maintain the required temperatures during storage, transportation, and processing, ensuring product quality and compliance with safety regulations.

Now, let’s examine the key considerations during the installation

Consideration 1: Cable Selection

Choosing the appropriate heat tracing cable is essential to meet specific temperature requirements and power output capabilities. It is crucial to select cables that are suitable for the intended application and environmental conditions.

Cable layout and insulation are equally important.

Consideration 2: Layout and Insulation

Optimal cable layout and proper insulation are necessary to ensure uniform heat distribution and minimize heat loss. Careful planning and implementation of these aspects guarantee the efficient performance of the heat tracing system.

Consideration 3: Maintenance and Monitoring

To maintain the effectiveness of these cables, regular inspections, testing, and maintenance are necessary. Monitoring the system for any faults or issues ensures prompt repairs and uninterrupted operation.

Conclusion:

Heat tracing cables provide numerous benefits in terms of temperature control, safety, and energy efficiency. Widely utilized in various industries, these cables ensure the smooth operation of pipelines, tanks, and equipment. By considering key installation factors and conducting regular maintenance, organizations can maximize the effectiveness and lifespan of their heat tracing systems.