Constant wattage heating cables are innovative and versatile and cost-efficient electrical devices designed to provide controlled and consistent heat in various applications. These cables are widely used in industries, commercial spaces, and residential settings where maintaining a specific temperature is crucial. Understanding the fundamentals of constant wattage heating cables is essential for appreciating their role in temperature control and the diverse range of applications they serve. Today at SVR Trace we are going to review this type of heating cables.

At its core, a constant wattage heating cable is a specialized electrical wire that generates a consistent amount of heat per unit length, regardless of the ambient temperature. Unlike some other heating systems, constant wattage cables do not rely on external controllers or sensors to adjust their output. Instead, they maintain a uniform heat output along their entire length, offering a straightforward and reliable solution for applications requiring a stable temperature.

The working principle of constant wattage heating cables is relatively straightforward. These cables are constructed with a conductive core, typically made of alloys with specific electrical properties. As electrical current flows through the cable, the resistance of the core generates heat. The key feature of constant wattage cables is that the heat output remains constant, providing a reliable and predictable source of warmth.

One of the primary advantages of constant wattage heating cables is their versatility in various applications. These cables are commonly used for freeze protection, temperature maintenance, and process heating. In industrial settings, they are employed to prevent pipes, valves, and tanks from freezing, ensuring continuous operations even in harsh weather conditions. In commercial buildings, constant wattage cables find use in maintaining optimal temperatures for piping systems, preventing damage and ensuring the efficient functioning of plumbing infrastructure.

These cables come in different types, catering to specific needs and environmental conditions. One common distinction is between self-regulating and non-self-regulating cables. Self-regulating cables dynamically adjust their heat output based on the surrounding temperature. As the temperature decreases, the cable’s electrical resistance increases, generating more heat. In contrast, non-self-regulating cables maintain a consistent output regardless of temperature changes. The choice between these types depends on the application requirements, making constant wattage cables adaptable to a wide range of scenarios.

The advantages of constant wattage heating cables extend beyond their simplicity and adaptability. These cables are known for their energy efficiency, as they only consume electricity when heat is required. The constant and controlled heat output contributes to overall energy savings, making them a sustainable and cost-effective solution for temperature management. Check our shop for the best heating cables and order now!

In conclusion, these cables play a crucial role in maintaining desired temperatures across diverse applications. Their reliable and consistent heat output, coupled with energy efficiency, make them a preferred choice in freezing prevention, temperature maintenance, and process heating. As we delve deeper into the various types, applications, and benefits of constant wattage heating cables, it becomes evident that these innovative devices are indispensable in ensuring the smooth operation of critical systems in challenging environmental conditions.

Visit our blog page for the newest content about industrial products and household products in the field of the underfloor heating!

- How a Constant Wattage Heating Cable Works?

- What are the applications of a Constant Wattage Heating Cable?

- What are the advantages of a Constant Wattage Heating Cable?

- What are the the types of a Constant Wattage Heating Cable?

- How is a Constant wattage heating cable installed?

- What are the Maintenance Tips of a Constant wattage heating cable?

- Is a Constant wattage heating cable energy-efficient and Cost Saving?

- What are the safety Features of a Constant Wattage Heating Cable?

- What are the future Trends and Innovations of a Constant wattage heating cable?

These are the questions that will be answered in this article. So lets continue!

Table of contents

- How a Constant Wattage Heating Cable Works?

- Applications of a Constant Wattage Heating Cable

- Advantages of a Constant Wattage Heating Cable

- Types of a Constant Wattage Heating Cable

- Installation and Maintenance Tips of a Constant wattage heating cable

- Energy Efficiency and Cost Savings of a Constant wattage heating cable

- Safety Features of a Constant Wattage Heating Cable

- Future Trends and Innovations of a Constant wattage heating cable

- FAQs

- Conclusion and summery

How a Constant Wattage Heating Cable Works?

Constant wattage heating cables are ingenious devices designed to generate and maintain a consistent amount of heat in a variety of applications. Understanding the fundamental principles of how these cables work is essential to appreciate their functionality and broad range of uses across different industries.

At the heart of a constant wattage heating cable lies a carefully engineered conductive core. Typically made from alloys with specific electrical properties, this core serves as the primary element responsible for heat generation. As electrical current flows through the cable, it encounters resistance within the conductive core. This resistance, in accordance with Ohm’s law, leads to the conversion of electrical energy into heat. The consequences can be seen in the quality and long-term support.

What distinguishes these type of cables from other heating solutions is their ability to maintain a uniform heat output per unit length. This consistency is achieved through the precise design of the conductive core and the cable as a whole. The cable is constructed to distribute the heat evenly along its entire length, ensuring that each section produces the same amount of warmth. One comparison can be with underfloor heating cables.

Unlike some heating systems that rely on external controllers or sensors to adjust their output based on ambient conditions, constant wattage cables do not require such intricate mechanisms. Instead, they operate independently, delivering a steady and unchanging level of heat. This inherent simplicity contributes to the reliability and ease of use associated with constant wattage heating cables.

The concept of constant wattage is rooted in the cable’s ability to provide a predetermined amount of power per unit length, regardless of variations in temperature. In other words, as the ambient temperature fluctuates, the heat output from the cable remains constant. This feature is particularly advantageous in applications where maintaining a specific temperature is critical, such as preventing freezing in pipes or ensuring the consistent performance of industrial processes and having an important role in the home heating industry and the environment.

To cater to different needs and environmental conditions, constant wattage heating cables come in various types. One significant distinction is between self-regulating and non-self-regulating cables. Self-regulating cables possess the unique ability to adjust their heat output based on the surrounding temperature. As temperatures decrease, the electrical resistance of the cable increases, resulting in higher heat production. This dynamic self-regulation makes these cables well-suited for applications where precise temperature control is essential.

On the other hand, non-self-regulating constant wattage cables maintain a constant heat output irrespective of changes in the ambient temperature. These cables are often employed in scenarios where a consistent level of warmth is required, and fluctuations in external conditions are not a concern. More details about trace-heating.

In conclusion, the functionality of these cables is grounded in the simple yet effective conversion of electrical energy into heat through a carefully engineered conductive core. The ability to maintain a consistent level of heat per unit length, regardless of external factors, sets these cables apart in the realm of temperature control solutions. Whether non-self-regulating heating cables or self-regulating heating cables, constant wattage heating cables continue to play a vital role in diverse applications, ensuring the reliability and efficiency and sustainability of management of temperatures in a wide range of environments.

Applications of a Constant Wattage Heating Cable

Constant wattage heating cables are versatile and efficient solutions employed in various industries and applications to maintain and regulate temperature in different environments. These cables, designed to deliver a consistent and uniform heat output, find widespread use due to their reliability and adaptability performing radiant floor heating. The applications of constant wattage heating cables span across industries, addressing diverse needs from freeze protection to process heating.

One prominent application of constant wattage heating cables is in freeze protection systems for pipes and tanks. In cold climates, water and other liquids can freeze, causing pipes and equipment to burst. These industrial cables are installed along the length of these pipes, preventing freezing and ensuring a continuous flow of liquids. This is crucial in industries such as oil and gas, chemical processing, and water treatment where maintaining fluidity is essential for operational efficiency and safety and can be for hydronic underfloor heating.

Another significant application lies in roof and gutter de-icing. In regions prone to snow and ice accumulation, constant wattage heating cables are installed on roofs and in gutters to prevent the formation of ice dams. These ice dams can lead to structural damage and leaks, posing a threat to buildings and infrastructure. By maintaining a consistent temperature, the heating cables prevent the formation of ice and contribute to the overall structural integrity of buildings so it is part of underfloor heating systems.

Constant wattage heating cables are also extensively used in industrial and manufacturing processes that require precise temperature control. These cables are employed for process heating in applications such as oil refining, petrochemical processing, and food production. The consistent heat output ensures that materials are maintained at optimal temperatures, promoting efficiency and product quality. In the pharmaceutical industry, for instance, these kind of cables play a vital role in maintaining the temperature of critical processes to meet stringent regulatory requirements.

The versatility of constant wattage heating cables extends to environmental control in instrumentation and control systems. In sensitive industries like electronics manufacturing, these cables are utilized to ensure that equipment and instruments are operating within specified temperature ranges somehow doing heat tracing cables job. This is crucial for maintaining the accuracy and reliability of delicate electronic components, preventing malfunctions and ensuring the longevity of the equipment.

In addition to industrial applications, these cables find use in residential and commercial settings. They are employed in floor heating systems, preventing cold spots and ensuring a comfortable indoor environment. These cables are also used in frost protection for outdoor areas such as driveways and sidewalks, enhancing safety by preventing the formation of ice in home heating systems.

In conclusion, these warmth producing cables are invaluable across a spectrum of applications due to their consistent and reliable heat output. From safeguarding critical industrial processes to preventing freezing in residential and commercial settings, these cables play a vital role in ensuring operational efficiency, safety, and comfort. As technology continues to advance, constant wattage heating cables are likely to evolve, offering even more innovative solutions for temperature control in diverse environments.

Advantages of a Constant Wattage Heating Cable

To continue the history of home heating, constant wattage heating cables offer several advantages that

make them a preferred choice for a wide range of applications. One primary benefit is their consistent and uniform heat output. Unlike self-regulating heating cables whose heat output varies with temperature, constant wattage cables provide a steady and predictable level of warmth. This reliability is crucial for maintaining precise temperatures in industrial processes, preventing freezing in pipelines, and ensuring consistent heat in various applications.

make them a preferred choice for a wide range of applications. One primary benefit is their consistent and uniform heat output. Unlike self-regulating heating cables whose heat output varies with temperature, constant wattage cables provide a steady and predictable level of warmth. This reliability is crucial for maintaining precise temperatures in industrial processes, preventing freezing in pipelines, and ensuring consistent heat in various applications.

Another advantage is the simplicity of installation. these type of heating cables are easy to install and require minimal maintenance. This makes them a cost-effective solution for both residential and industrial applications like high qualified heating cable with inactive copper. The straightforward installation process also contributes to quicker deployment and reduces labor costs associated with complex heating systems.

Durability is a key feature of these cables. Designed to withstand harsh environmental conditions and chemical exposure, these cables demonstrate longevity and reliability in challenging settings. This durability ensures a prolonged service life, reducing the need for frequent replacements and minimizing downtime in industrial processes.

Furthermore, constant wattage heating cables are versatile and adaptable to different environments and temperature requirements. Their wide range of applications includes freeze protection, roof and gutter de-icing, process heating, and environmental control. This versatility makes them a valuable and flexible solution for diverse heating needs making them related to thermostats and their role in home heating.

In summary, the advantages of constant wattage heating cables lie in their consistent heat output, ease of installation, durability, and versatility. These qualities make them a reliable and cost-effective choice for maintaining temperature control in various settings, from industrial processes to residential heating applications like household underfloor heating.

Types of a Constant Wattage Heating Cable

As an story of underfloor heating these cables come in various types, each designed to address specific heating requirements in different applications. Understanding the distinctions between these types is crucial for selecting the most suitable solution for a particular use case.

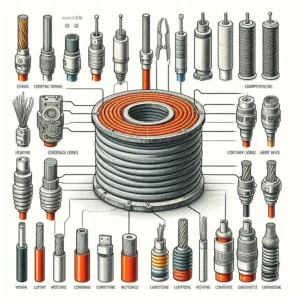

1. Parallel Constant Wattage Heating Cables:

These cables consist of a continuous length of wire with a uniform wattage per unit length. They are easy to install and suitable for applications like pipe tracing and freeze protection.

2. Series Constant Wattage Heating Cables:

Unlike parallel cables, series these cables have a fixed length and deliver a constant wattage across the entire cable. They are often used for process heating applications where precise temperature control is essential. Heating straps can be a good example. Oh! There is an excellent underfloor heating strap in our shop.

3. Mineral-Insulated Constant Wattage Heating Cables:

These cables feature a mineral-insulated construction, offering enhanced durability and resistance to harsh environments. They are commonly employed in industrial settings, particularly in chemical processing and petrochemical industries like oil and gas industries and underfloor heating.

4. Overlapped Constant Wattage Heating Cables:

Overlapped cables are designed to provide a higher wattage output in specific areas, allowing for customized heating solutions. This type is versatile and finds use in applications requiring varying heat distribution.

5. Low-Temperature Constant Wattage Heating Cables:

Specifically designed for low-temperature applications, these cables are ideal for frost protection and preventing freezing in pipes, roofs, and gutters in cold climates.

Each type of these cable has its unique characteristics, making it well-suited for specific heating challenges. The selection of the appropriate type depends on factors such as the intended application, environmental conditions, and the desired level of temperature control. This might interest you in installation process of underfloor heating systems.

Installation and Maintenance Tips of a Constant wattage heating cable

Proper installation and maintenance are essential for ensuring the effective and reliable operation of constant wattage heating cables. Here are key tips to consider:

Installation Tips:

1. Follow Manufacturer Guidelines:

Adhere to the manufacturer’s installation guidelines and specifications. These guidelines provide critical information on cable spacing, termination details, and electrical requirements.

2. Ensure Proper Grounding:

Establish a robust grounding system to enhance the safety and performance of the heating cable. Proper grounding helps prevent electrical issues and ensures efficient heat distribution this can elevate house like elevated kitchens by underfloor heating.

3. Avoid Overlapping:

When installing cables, avoid overlapping or crossing them, as this can lead to uneven heating and potential hotspots. Maintain a consistent spacing according to the manufacturer’s recommendations. This can show ease and comfort of underfloor heating systems.

4. Secure Proper Insulation:

Insulate the heating cable adequately to maximize its efficiency. Use approved insulation materials and techniques to prevent heat loss and enhance the overall effectiveness of the system.

5. Verify Voltage Compatibility:

Confirm that the heating cable’s voltage matches the electrical system to avoid compatibility issues. Mismatched voltages can compromise performance and safety.

Maintenance Tips:

1. Regular Inspections:

Conduct routine visual inspections of the heating cable system to identify any signs of wear, damage, or degradation. Early detection can prevent potential issues and extend the lifespan of the cables.

2. Check for Continuity:

Periodically test the continuity of the heating cable to ensure it is functioning as intended. Use appropriate testing equipment to identify any breaks or defects in the cable.

3. Monitor Control Systems:

If the heating cable is part of a larger control system, regularly check and calibrate temperature control devices. This ensures that the cable operates within the specified temperature range. So you should be alert for the hazard zones of underfloor heating.

4. Clear Debris and Obstructions:

Keep the surrounding area free of debris and obstructions to maintain proper heat distribution. Accumulated snow, ice, or other materials can hinder the cable’s effectiveness.

5. Document Maintenance Activities:

Keep detailed records of maintenance activities, including inspection dates, repairs, and any modifications made to the heating cable system. This documentation helps in tracking the system’s performance over time.

By following these installation and maintenance tips, users can optimize the performance and longevity of constant wattage heating cables, ensuring their reliability in various applications and also ensuring the health benefits of underfloor heating systems.

Energy Efficiency and Cost Savings of a Constant wattage heating cable

Constant wattage heating cables contribute significantly to energy efficiency and cost savings, making them a preferred choice for various heating applications. Here are key factors highlighting their positive impact:

1. Targeted Heating:

these heating cables deliver heat consistently, ensuring that energy is directed precisely where it is needed. This targeted heating approach minimizes energy waste by avoiding unnecessary overheating and reducing overall energy consumption.

2. Efficient Operation:

These cables are designed to maintain a consistent temperature, preventing excessive energy usage during periods of inactivity. This can make a good progress in industry and the underfloor heating systems. The efficient operation of these warmth producing cables is particularly valuable in applications such as pipe tracing and frost protection, where maintaining a specific temperature is crucial.

3. On-Demand Heating:

Unlike some heating systems that operate continuously, constant wattage heating cables are activated on-demand. This means they only consume energy when necessary, providing a more efficient and cost-effective solution for applications like roof and gutter de-icing or floor heating.

4. Reduced Heat Loss:

Properly insulated constant wattage heating cables help minimize heat loss, ensuring that the generated warmth is effectively utilized specially in open space heating and heating cables This reduction in heat loss contributes to energy efficiency and can result in substantial cost savings over time.

5. Longevity and Durability:

Constant wattage heating cables are designed for durability, offering a long lifespan with minimal maintenance requirements. The longevity of these cables translates into reduced replacement costs and lower overall lifecycle expenses, contributing to long-term cost savings.

6. Customized Solutions:

With various types and configurations available, these cables allow for customized solutions tailored to specific heating needs. This flexibility ensures that the system is optimized for efficiency, providing the right amount of heat in the right places. You might try the best underfloor heating film.

In summary, the energy efficiency and cost savings associated with constant wattage heating cables stem from their targeted heating, on-demand operation, reduced heat loss, and long-term durability. As businesses and homeowners seek sustainable and cost-effective heating solutions, these cables emerge as a reliable choice that not only meets heating requirements but also promotes resource efficiency.

Safety Features of a Constant Wattage Heating Cable

These cables are equipped with various safety features to ensure the reliable and secure operation of the heating system. These features contribute to the prevention of electrical hazards and protect both the equipment and the surrounding environment. Here are key safety features associated with constant wattage heating cables:

1. Over-Temperature Protection:

Many of these cables are designed with built-in over-temperature protection mechanisms. These features automatically limit the cable’s temperature to prevent overheating, reducing the risk of damage or fire hazards.

2. Ground Fault Protection:

Ground fault protection is crucial for electrical safety. This type of heating cable often incorporate ground fault detection to identify and mitigate any potential ground faults, minimizing the risk of electric shock or system failure. An example can be the best parallel silicone heating cable.

3. Self-Regulating Technology:

Some constant wattage heating cables utilize self-regulating technology. This feature causes the cable’s power output to decrease as the temperature rises, providing an inherent safeguard against excessive heat. This self-regulation helps prevent overheating and ensures safe and efficient operation. Somehow related working system can be : Rails and switch points and heating cables.

4. Moisture Resistance:

Constant wattage heating cables designed with moisture-resistant materials are better equipped to withstand wet or damp conditions. This feature is especially important in outdoor applications or environments where moisture exposure is likely. Might interest you in hydrogen process and heat-tracing.

5. Corrosion Resistance:

In corrosive environments, constant wattage heating cables with corrosion-resistant coatings or materials protect against degradation over time. This corrosion resistance enhances the longevity of the cable and maintains its safety and performance.

6. Certifications and Compliance:

Reputable constant wattage heating cables undergo testing and certification processes to ensure they meet safety standards and regulations. Compliance with industry standards provides assurance that the cables are manufactured and tested to deliver safe and reliable performance.

7. Durable Insulation:

The insulation material used in constant wattage heating cables plays a crucial role in safety. Durable insulation enhances the cable’s resistance to environmental factors and electrical wear, contributing to the overall safety and reliability of the system.

These safety features collectively make constant wattage heating cables a secure and dependable choice for various applications, including freeze protection, pipe tracing, and roof de-icing like the best drain-line heating cable. When properly installed and maintained, these cables provide a safe and efficient solution for temperature control in diverse environments.

Future Trends and Innovations of a Constant wattage heating cable

As technology continues to advance, constant wattage heating cables are poised to see several future trends and innovations that enhance their efficiency, sustainability, and adaptability across diverse applications.

1. Smart and IoT Integration:

The integration of constant wattage heating cables with smart technologies and the Internet of Things (IoT) is a prominent trend. This enables remote monitoring, control, and optimization of heating systems, offering increased energy efficiency and real-time insights into performance.

2. Energy Harvesting:

Future innovations may explore the incorporation of energy harvesting technologies within constant wattage heating cables. This could involve the utilization of ambient energy sources, such as solar or kinetic energy, to supplement the power requirements of the heating system, making it more sustainable.(other product: Heating cable with two power ratings)

3. Advanced Materials:

Ongoing research in materials science is likely to result in the development of advanced materials for constant wattage heating cables. These materials could enhance durability, flexibility, and resistance to environmental factors, contributing to longer service life and improved performance.

4. Self-Diagnostic Capabilities:

The incorporation of self-diagnostic features in constant wattage heating cables is anticipated. These features would enable the cable to identify potential issues, such as faults or damage, and communicate this information to the user or control system for timely maintenance or repairs.

5. Improved Efficiency and Energy Conservation:

Innovations focused on improving the overall efficiency of constant wattage heating cables and optimizing energy conservation are expected. This could involve the development of advanced control algorithms, sensors, and thermal management systems to achieve more precise temperature control and minimize energy consumption.

6. Customization and Modularity:

Future trends may see increased customization and modularity in constant wattage heating cable systems. This would allow users to tailor the heating solution to specific requirements, providing a more flexible and adaptive approach to temperature control.

7. Environmental Sustainability:

The growing emphasis on sustainability is likely to influence the design of constant wattage heating cables. Manufacturers may explore eco-friendly materials, manufacturing processes, and end-of-life recycling options to align with broader environmental goals.

In conclusion, the future of constant wattage heating cables holds exciting possibilities, driven by advancements in smart technologies, materials science, and a focus on sustainability used in silo heating with heating cables. These innovations are expected to enhance the performance, efficiency, and environmental impact of constant wattage heating cable systems, making them even more valuable solutions for temperature control in various applications.

FAQs

1. What is a constant wattage heating cable?

A constant wattage heating cable is an electrical heating element designed to provide a consistent and uniform heat output. It is used for applications such as freeze protection, pipe tracing, roof and gutter de-icing, and industrial process heating.*

2. How does a constant wattage heating cable work?Constant wattage heating cables maintain a steady power output, generating heat consistently along their entire length. This is achieved through a fixed resistance per unit length, ensuring a reliable and predictable level of warmth.

3. Where are constant wattage heating cables commonly used?

They are commonly used in various applications, including freeze protection for pipes, roof and gutter de-icing, process heating in industrial settings, floor heating in residential buildings, and environmental control for instrumentation.

4. Are constant wattage heating cables energy-efficient?

Yes, constant wattage heating cables can be energy-efficient due to their targeted heating and on-demand operation. They only consume energy when necessary, contributing to efficiency and potential cost savings.

5. Can constant wattage heating cables be used for outdoor applications?

Yes, these cables are suitable for outdoor applications, including roof and gutter de-icing, and frost protection for driveways and sidewalks.

6. Do constant wattage heating cables require special installation?

They require proper installation following manufacturer guidelines. Installation considerations include spacing, grounding, and insulation to ensure safe and effective operation. See some tips about loading and unloading process of heating cables.

7. How do constant wattage heating cables differ from self-regulating cables?

Constant wattage cables provide a consistent heat output, while self-regulating cables adjust their power output based on the surrounding temperature. Constant wattage cables are ideal for applications where a steady heat output is required.

8. Can constant wattage heating cables be cut to length?

Most constant wattage heating cables cannot be cut to length, as this can alter the electrical characteristics and compromise their performance. It’s essential to follow the manufacturer’s guidelines for proper installation.

9. Are constant wattage heating cables suitable for hazardous environments?

Yes, some constant wattage heating cables are designed for use in hazardous environments and are constructed with materials that resist corrosion and maintain safety in challenging conditions.

10. How long do constant wattage heating cables typically last?

The lifespan of constant wattage heating cables depends on factors such as usage, environmental conditions, and maintenance. With proper installation and care, they can last for many years, providing a reliable heating solution. Some tips about maintenance of underfloor heating.

Conclusion and summery

In conclusion, constant wattage heating cables emerge as indispensable solutions for temperature management, offering a reliable and efficient way to generate and maintain heat in diverse applications. Their fundamental design, centered around a carefully engineered conductive core, allows for a consistent and predetermined amount of heat per unit length, distinguishing them from other heating solutions.

The versatility of constant wattage heating cables is evident in their widespread use across industries, from preventing freezing in pipes to ensuring the smooth operation of industrial processes. Trace heating also has a crucial role in it like LNG tanks and trace heating. Their ability to operate independently, without the need for complex external controllers, adds to their appeal, simplifying installation and maintenance processes.

The comparison with other heating solutions highlights the advantages of constant wattage cables, such as their uniform heat output, energy efficiency, and reliability. These attributes make them a preferred choice in scenarios where maintaining a specific temperature is crucial, contributing to cost savings and sustainable energy practices. We can also see how roofs and gutters work due to this.

Constant wattage heating cables play a crucial role in enhancing safety, protecting infrastructure, and optimizing processes by providing a controlled and consistent heat source. As technology continues to advance, these cables are likely to witness further innovations, ensuring their relevance and effectiveness in addressing the evolving needs of temperature control across a wide range of applications. In the ever-changing landscape of heating solutions, constant wattage heating cables stand as reliable and adaptable contributors to efficient thermal management.